.jpg?width=407&resizemode=force)

The Vitesco Technologies Group became part of the Schaeffler Group as of October 1, 2024, due to the merger of Vitesco Technologies Group AG into Schaeffler AG.

Please note: Legal or actual changes since October 1, 2024, are therefore no longer reflected in the content of the website.

As the website is no longer updated, we assume no liability for the content of this website, or the linked websites contained therein. The operators of the linked sites are solely responsible for their content.

Irrespective of this, you can still find the current BPCoC and the General Terms and Conditions of Purchase at Vitesco Technologies - Suppliers (vitesco-technologies.com)

Under the following link you will find the current Schaeffler website:

.jpg?width=407&resizemode=force)

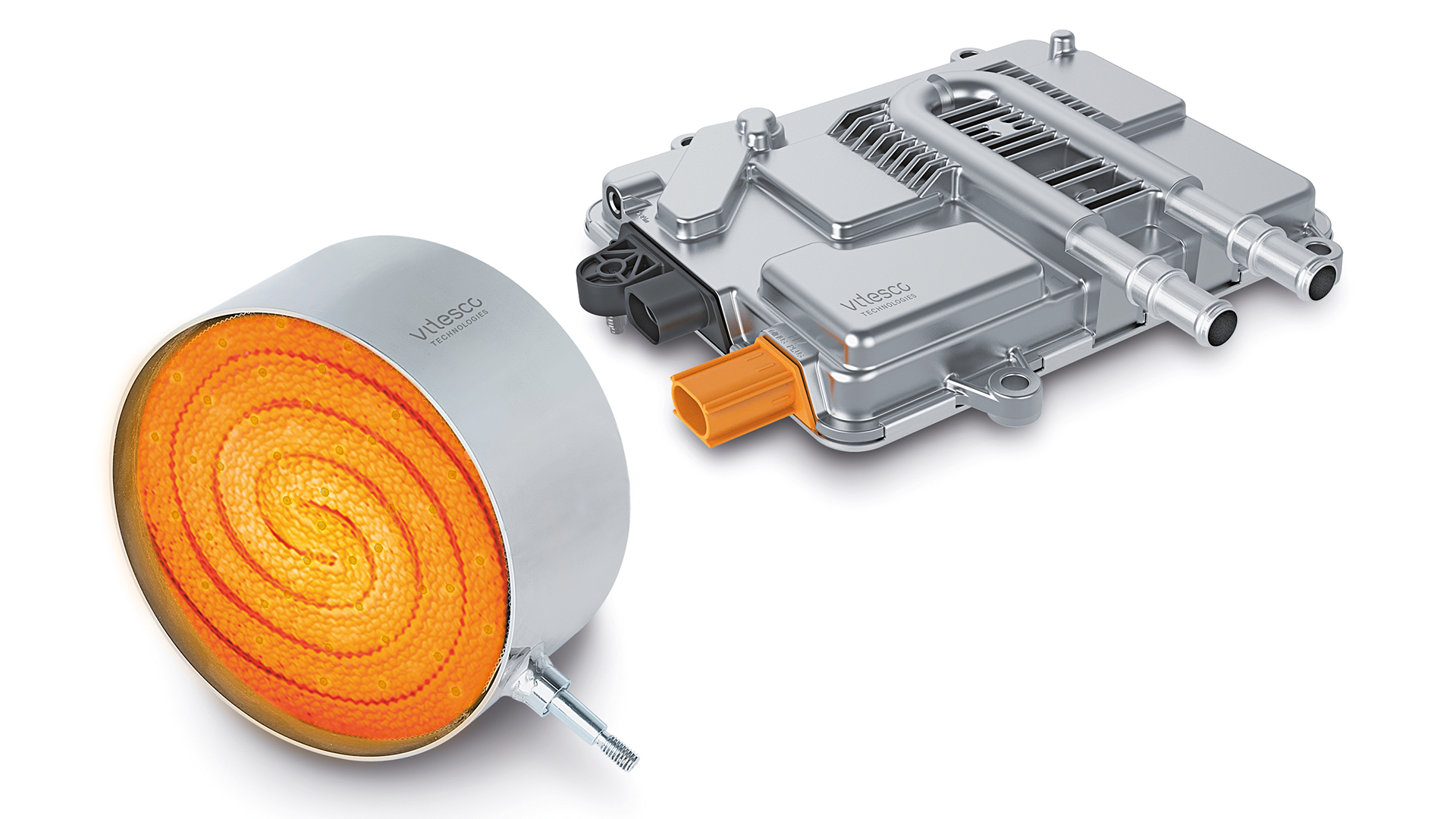

Regensburg, February 22, 2021. Vitesco Technologies, a leading international supplier of advanced powertrain technologies and electrification solutions, is now making electrical catalyst heating available in high-voltage hybrid vehicles as well. Thanks to a new DC/DC converter, the heating discs of the electrically heated EMICAT catalyst can now also be supplied with electricity in high-voltage vehicles. It is already in use in vehicles with a pure combustion engine or in mild hybrids.

For Vitesco Technologies, the novel use of heating technology in the high-voltage sector is an extension of its existing product range. The innovative e-catalyst enables lowest emissions in real operation – something that is becoming increasingly important in light of forthcoming regulations such as Euro 7.

Hybrid vehicles utilize their potential for CO2 savings by shutting off the combustion engine as often as possible and using electric power instead. This results in longer operating pauses in the combustion engine during which the vehicle does not emit CO2. During these phases, the engine cools down. If it is required and restarted, the exhaust flow is also cold at first – possibly too cold to convert pollutant gases in the catalyst. “In other words, the cold start is actually the rule, especially with efficiently-driven hybrids,” says Rolf Brück, head of Catalysts and Filters at Vitesco Technologies. “From the perspective of emission reduction, this is a challenge, as the greatest share of the emissions in a cycle can be generated during cold start situations.” If you want to make the best possible use of electrification in a vehicle to save CO2, a solution is required for all cold start events.

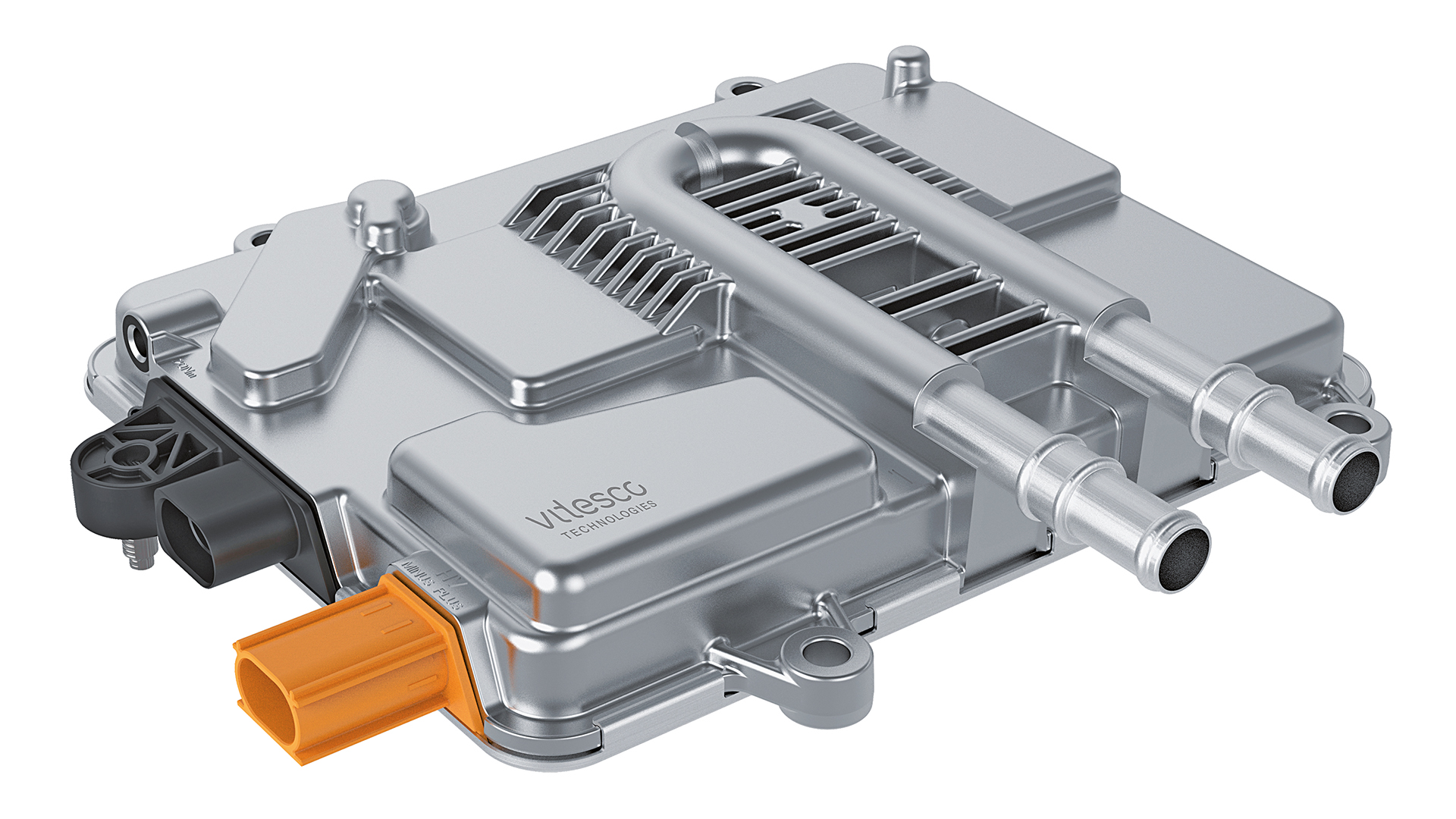

This form of exhaust gas aftertreatment has so far not been available for high-voltage hybrids – such as the increasingly popular plug-in hybrid – because the heating disc cannot be supplied directly from the high-voltage system at 200-450 V. The newly-developed DC/DC converter now generates the low voltage and power for the heating disc from the high voltage of the drive system. The compact unit is based on state-of-the-art printed circuit board technology and the latest components with small dimensions, and enables a high degree of efficiency of 95%.

The system solution, consisting of heating disc and DC/DC converter, upgrades exhaust-gas aftertreatment systems for even stricter emission standards worldwide in the future.

Vitesco Technologies is one of only a few suppliers worldwide to offer the full range of electronics, software and system integration for powertrain electrification. The portfolio of innovative solutions for 48-volt systems and plug-in hybrids up to completely battery-based electric drives is correspondingly large. Examples include highly complex power electronics, intelligent sensor technologies, integrated axle drives as well as battery, energy and thermal management systems. This bandwidth makes it possible to supply fully developed individual components and at the same time develop sophisticated holistic systems - all from a single source.

Thanks to a new DC/DC converter, the heating discs of the electrically heated EMICAT catalyst can now also be supplied with electricity in high-voltage vehicles. This enables an additional option for electrification to the market.

© Vitesco Technologies GmbH (exclusive rights)

The innovative e-catalyst enables lowest emissions in real operation – something that is becoming increasingly important in light of forthcoming regulations such as Euro 7.

© Vitesco Technologies GmbH (exclusive rights)

The perfect combination of Vitesco Technologies’ tried-and-tested EMICAT heated catalyst and the new DC/DC converter reduces real emissions in critical situations.

© Vitesco Technologies GmbH (exclusive rights)