.jpg?width=407&resizemode=force)

The Vitesco Technologies Group became part of the Schaeffler Group as of October 1, 2024, due to the merger of Vitesco Technologies Group AG into Schaeffler AG.

Please note: Legal or actual changes since October 1, 2024, are therefore no longer reflected in the content of the website.

As the website is no longer updated, we assume no liability for the content of this website, or the linked websites contained therein. The operators of the linked sites are solely responsible for their content.

Irrespective of this, you can still find the current BPCoC and the General Terms and Conditions of Purchase at Vitesco Technologies - Suppliers (vitesco-technologies.com)

Under the following link you will find the current Schaeffler website:

.jpg?width=407&resizemode=force)

Powertrain electrification holds the key to sustainable future mobility. Vehicles with electrified powertrain architectures, such as battery electric (EV), hybrid (HEV), and fuel cell electric (FCEV), will shape the propulsion landscape over the next decade.

As an electrification pioneer, Vitesco Technologies offers propulsion solutions for all types of electrified vehicles based on our long-standing expertise in powertrain systems, ranging from stand-alone components, to intelligent operating strategies and full turn-key systems. The future of mobility is electric.

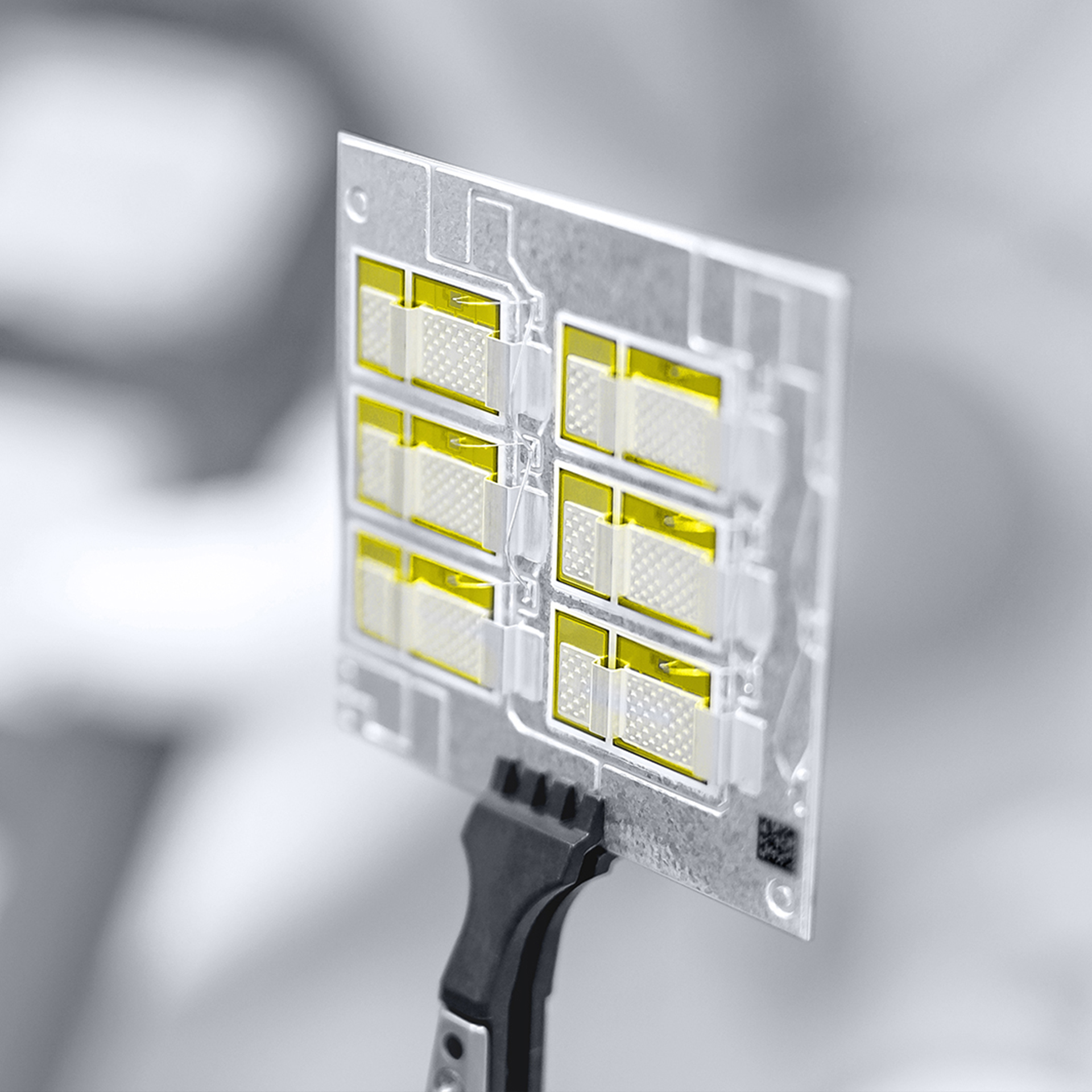

Intelligent, networked powertrain electronics are the brain of efficient and clean propulsion systems. While this was already true on internal combustion engine (ICE) powertrains, smart electronics are even more prominent in electrified vehicles.

While continuing to deliver ever higher performance, powertrain electronics are also undergoing a transformation within the vehicle electrical and electronic (E/E) architecture. As the typical vehicle migrates from distributed electronics, towards domain-based, cross-domain and even server-based architectures, Vitesco Technologies, with its strong DNA in both electronics and software, remains at the forefront in enabling car makers to manage the ever-increasing complexity of electronics across their vehicle fleets.

Intelligent, networked powertrain electronics are key elements of efficient and clean propulsion in modern vehicles. While this was already true on internal combustion engine (ICE) based powertrains, the trend is even more prominent in HEVs and EVs.

In addition to delivering top performance and robustness, powertrain electronics are also undergoing a transformation within the vehicle electrical and electronic (E/E) architecture. As the typical vehicle E/E architecture migrates from distributed electronics, towards Domain, Cross-Domain and even Server based architectures, Vitesco Technologies, with its strong DNA in both electronics and software, remains at the forefront in enabling car makers to manage the ever-increasing complexity of electronics across their vehicle fleets.

Low-voltage electrification, in combination with continued improvements in the combustion engine, makes a valuable contribution to further reduction of vehicle carbon dioxide (CO2) and pollutant emissions. Such mild-hybrid electrification, e.g. 48-volt electrification of ICE powertrains is a compelling low-cost hybridization option for many vehicles and its adoption is already underway on a large scale across car maker fleets.

Outlook: With innovations like the 48-volt HighPower electric motor, Vitesco Technologies enables low-speed purely electric urban driving at an attractive low cost. The 48-volt HighPower motor also increases energy recuperation in the hybrid vehicle and provides higher torque assistance to the ICE, resulting in even higher fuel and CO2 savings.

Vitesco Technologies was among the first suppliers to launch an electric high-voltage (HV) axle drive with integrated power electronics and reducer, into volume series production at the end of 2019. This launch was the result of twelve years of high-voltage technology development. As early as 2007, Vitesco Technologies began development of the powertrain for the first generation of the Renault Zoe and has been advancing HV propulsion technology ever since.

HV drive solutions used in EVs as well as in FCEVs, facilitate locally emission-free driving. We are already on the path towards zero emission mobility and Vitesco Technologies is among the pioneers.

In Hybrid powertrains, HV systems operate in tandem with an ICE, to significantly lower vehicle CO2 emissions. Hybrid powertrains provide a substantial positive impact on car maker fleet fuel consumption globally.

Outlook: To reduce Plug-in Hybrid Electric Vehicle (PHEV) cost and to thus increase its market penetration, Vitesco Technologies has developed the innovative “Cost-efficient PHEV” concept, which integrates the transmission and electric motor, while also facilitating an intelligent compact all-wheel-drive solution.

To increase the efficiency and range of electric powertrains, Vitesco Technologies is developing inverters utilizing state-of-the-art silicon carbide technology (SiC).

How can you “refuel” an electric vehicle efficiently, fast, and with maximum comfort?

Depending on the available infrastructure, type of vehicle and use case, the answer can be found in different solutions.

Vitesco Technologies has scalable charging technologies for global applications, with its family of on-board chargers (OBC) for standard alternating current (AC) charging, and vehicle junction unit for fast high-power direct current (DC) charging. The OBC covers a range of charging power and is capable of interfacing with electric grids worldwide.

The OBC is also a key device around which other HV components are often integrated into a “High Voltage Box”, enabling the car maker to reduce the overall size, weight and cost of HV electronics and wiring harnesses in the vehicle.

FCEVs combine the efficiency of an electric drive while using hydrogen (H2) as the energy carrier, which is converted to electricity during driving. Since the H2 onboard supply can be quickly refilled, FCEVs are suitable for long-distance driving – plus they are very clean as they emit neither CO2 nor pollutants during operation.

Heavy commercial vehicles, which would otherwise require very large batteries for pure electric mobility, can especially benefit from fuel cell technology as a viable alternative to the diesel engine.

For Vitesco Technologies, the long driving range and zero emissions are the motivation for our work on optimizing fuel cell systems. In addition to the re-use of our existing portfolio of sensors, actuators, and electronics, our development also includes the fuel cell stack, in partnership with a leading university in Germany.

© Vitesco Technologies GmbH (exclusive rights)

Smart thermal management significantly extends the driving range of an EV or HEV by maximizing the use of battery energy for real driving. By careful re-use of heat energy in the car for air conditioning of the vehicle interior, thermal management conserves battery energy for extending vehicle driving range, and its benefits are especially significant at hot and cold temperature extremes.

Vitesco Technologies’ thermal management solutions cover a full-system scope, from control strategies to intelligent components such as electric coolant pumps, multi-port valves, and sensors. We manage both temperature extremes by flexible distribution of heat generated by powertrain components during operation. By allowing all components to operate at their optimal temperatures, our thermal management solutions reduce charging times and prolong battery life.