.jpg?width=407&resizemode=force)

The Vitesco Technologies Group became part of the Schaeffler Group as of October 1, 2024, due to the merger of Vitesco Technologies Group AG into Schaeffler AG.

Please note: Legal or actual changes since October 1, 2024, are therefore no longer reflected in the content of the website.

As the website is no longer updated, we assume no liability for the content of this website, or the linked websites contained therein. The operators of the linked sites are solely responsible for their content.

Irrespective of this, you can still find the current BPCoC and the General Terms and Conditions of Purchase at Vitesco Technologies - Suppliers (vitesco-technologies.com)

Under the following link you will find the current Schaeffler website:

.jpg?width=407&resizemode=force)

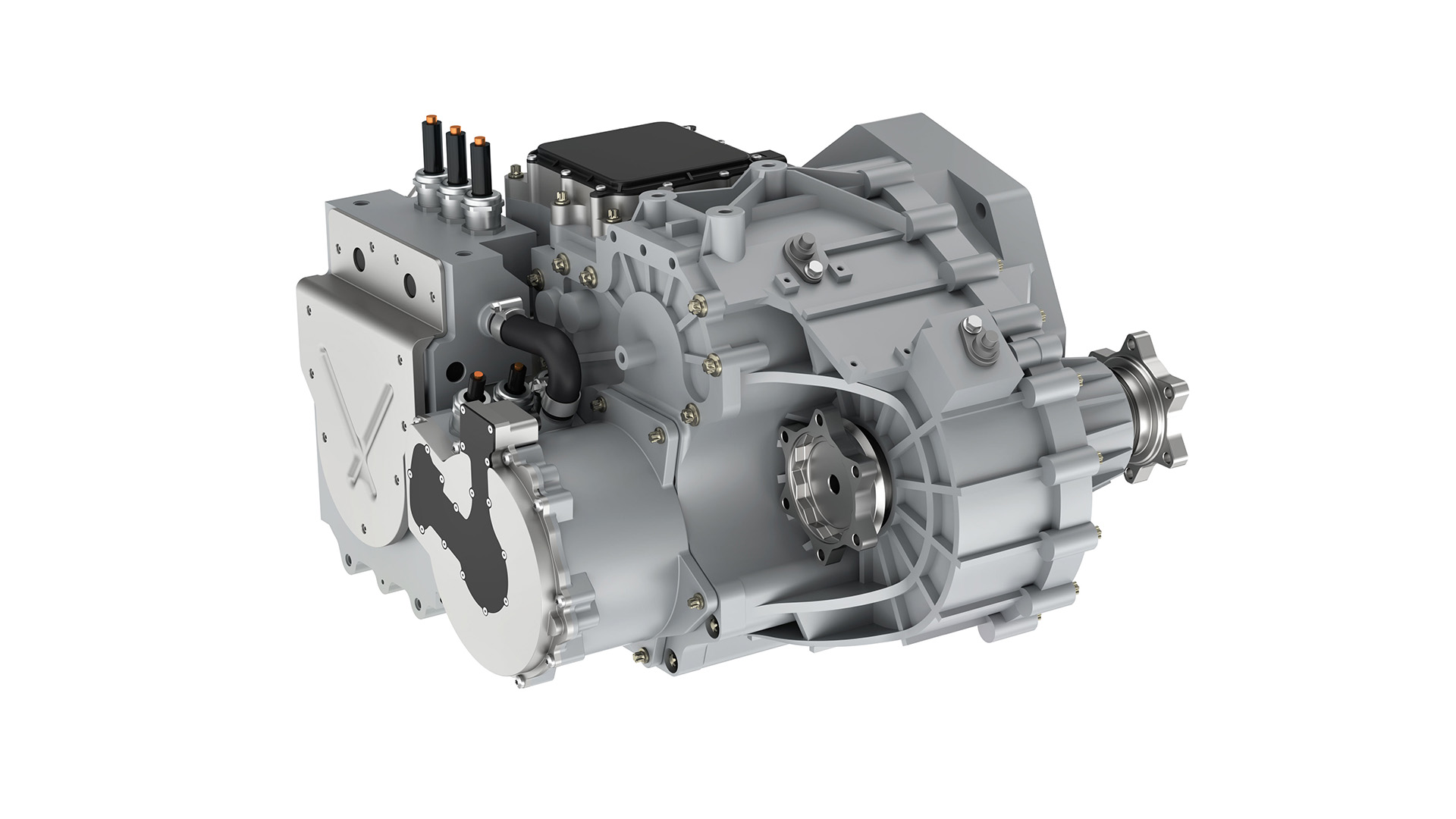

Regensburg, December 9, 2019. Vitesco Technologies, the Powertrain business area of Continental, premiered an extremely cost-effective and compact hybrid transmission solution with integrated electric machines, designed for use in applications such as Plug-in Hybrid Electric Vehicles (PHEVs), at the CTI Symposium in Berlin from December 9-12, 2019.

Vitesco Technologies is using its know-how in the field of powertrain electrification to pave the way for genuinely affordable hybrid vehicles. The task is made all the more challenging by the fact that a hybrid has two power sources – an internal combustion engine and an electric motor, complete with power electronics and battery. This additional technical infrastructure can raise the cost of an all-electric-capable high-voltage hybrid to a level that prohibits significant market penetration. If hybrid vehicles, which are now often capable of an electric driving range of 50 km or more, weren’t so expensive, they could potentially play a significant role in reducing CO2 emissions from everyday driving.

Vitesco Technologies has now come up with a solution: The key here was to break with conventional thinking on powertrain design and develop a concept that reassigns a number of functions previously performed by the transmission. At the heart of Vitesco Technologies’ solution is the expanded role played by the electric motor, which no longer simply acts as a means of propulsion and energy recuperation.

“So far it has not been possible to tap the full potential of plug-in hybrids and full hybrids for reducing CO2 emissions because the high cost of these vehicles’ powertrains puts them out of reach for many customers,” says Stephan Rebhan, Head of Technology & Innovation at Vitesco Technologies. “We have identified further potential here which our DHT technology for cost-effective PHEVs is designed to leverage. With a view to cutting CO2 emissions, PHEVs are a form of electric mobility which deserves to become much more successful in the future.”

The basic aim of DHT technology for cost-effective PHEVs is to permit the design of very compact automatic transmissions with an integrated high-voltage electric motor on the output side of the transmission. Vitesco Technologies’ cost-effective PHEV prototype offers the driver the same standard of comfortable driving and shifting that until now has been associated with plug-in hybrids equipped with a conventional 6-speed automatic transmission. But a DHT transmission with Vitesco technology has only four mechanical gears and has no mechanical synchromesh systems, auxiliary hydraulics or start clutch. Starting up (in 1st and 2nd gear) and backing up are handled by the electric drive motor, while synchronization is performed by a starter-alternator that also ensures that the internal combustion engine starts quickly and smoothly. The reassignment of functions makes it possible to reduce the number of mechanical components in the transmission, which also saves space, weight and costs. This makes the DHT a natural choice for front transverse mounting in compact segment vehicles, where installation space always presents a challenge.

DHT technology, combined for example with a low-cost port-injection gasoline engine and all-electric-capable electric drive, clears the way for affordable, economical and comfortable vehicles capable of performing a wide range of daily trips in all-electric mode, with zero local emissions. The DHT for cost-effective PHEVs is designed for speeds of up to 120 km/h in all-electric mode, and up to 160 km/h in hybrid mode.

This new PHEV solution draws on Vitesco Technologies’ wide-ranging systems expertise in terms of overall powertrain design, and comprehensive knowledge of electric drive technology. The smooth, quiet shifting of the DHT despite its simple dog-clutch design is made possible thanks to the high dynamic capability of the electric motor functions, which in turn requires a profound understanding of the relevant control technology. DHT technology for low-cost PHEVs marks a further step in Vitesco Technologies’ systematic electrification strategy. “To ensure compliance with future EU CO2 emissions limits, it will be particularly important to get a grip on costs, which currently act as a barrier to the wider market success of hybrid electric powertrains,” concludes Rebhan.

To ensure compliance with future EU CO2 emissions limits, it will be particularly important to get a grip on costs.

© Vitesco Technologies GmbH (exclusive rights)

Vitesco Technologies Plug-In-Hybrid on the test track at the CTI Symposium in Berlin.

© Vitesco Technologies GmbH (exclusive rights)

Vitesco Technologies Plug-In-Hybrid on the test track at the CTI Symposium in Berlin.

© Vitesco Technologies GmbH (exclusive rights)

Vitesco Technologies Plug-In-Hybrid on the test track at the CTI Symposium in Berlin.

© Vitesco Technologies GmbH (exclusive rights)

From left: Andreas Riedel, Kiarash Sabzewari, Stefan Rohrer und Jörg Sagstetter (all from Vitesco Technologies)

© Vitesco Technologies GmbH (exclusive rights)

Cost-effective and compact hybrid transmission solution with integrated electric machines.

© Vitesco Technologies GmbH (exclusive rights)