.jpg?width=407&resizemode=force)

The Vitesco Technologies Group became part of the Schaeffler Group as of October 1, 2024, due to the merger of Vitesco Technologies Group AG into Schaeffler AG.

Please note: Legal or actual changes since October 1, 2024, are therefore no longer reflected in the content of the website.

As the website is no longer updated, we assume no liability for the content of this website, or the linked websites contained therein. The operators of the linked sites are solely responsible for their content.

Irrespective of this, you can still find the current BPCoC and the General Terms and Conditions of Purchase at Vitesco Technologies - Suppliers (vitesco-technologies.com)

Under the following link you will find the current Schaeffler website:

.jpg?width=407&resizemode=force)

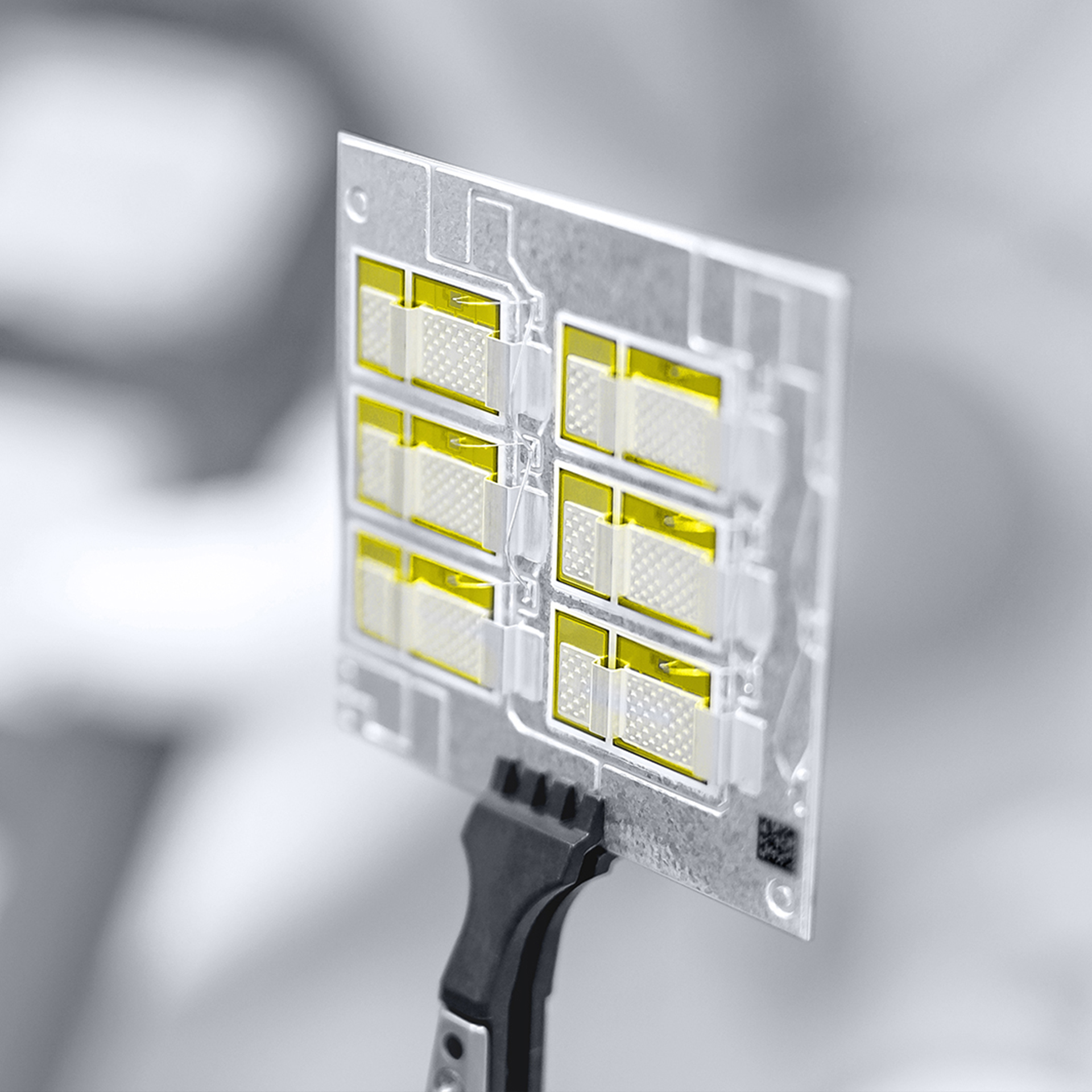

Circular economy (CE) is an economic system that aims to eliminate waste throughout an entire value chain – including sourcing, manufacturing and use. The automotive industry is responsible for a large share of resource consumption and waste generation, especially with the increasing demand for electric vehicles. By implementing circular economy approaches, such as vehicle sharing, smart charging, refurbishing, repurposing, and recycling, the automotive industry can reduce its environmental impact, save costs, and create new business opportunities. Today, the whole automotive industry is pushing towards a more circular-economy business model.

The 10-R principle in the context of a CE is a model that outlines various strategies to retain the value of resources. Each ‘R’ represents a different approach to preserving value, ranging from refusing to use unnecessary resources, to recovering energy from waste. The 10 Rs can be separated into three groups.

There are already guidelines that can be used for circular product design. For example, the “Design for Environment” guidelines foster a “Recycling Passport” approach aiming to document the percentage of recyclability of the product according to relevant information (weight, material, % recycled, …) provided through a table that lists each component.

Vitesco Technologies is proactively implementing best practices to make its products as sustainable as possible to deliver their share for a better and more sustainable future.