.jpg?width=407&resizemode=force)

The Vitesco Technologies Group became part of the Schaeffler Group as of October 1, 2024, due to the merger of Vitesco Technologies Group AG into Schaeffler AG.

Please note: Legal or actual changes since October 1, 2024, are therefore no longer reflected in the content of the website.

As the website is no longer updated, we assume no liability for the content of this website, or the linked websites contained therein. The operators of the linked sites are solely responsible for their content.

Irrespective of this, you can still find the current BPCoC and the General Terms and Conditions of Purchase at Vitesco Technologies - Suppliers (vitesco-technologies.com)

Under the following link you will find the current Schaeffler website:

.jpg?width=407&resizemode=force)

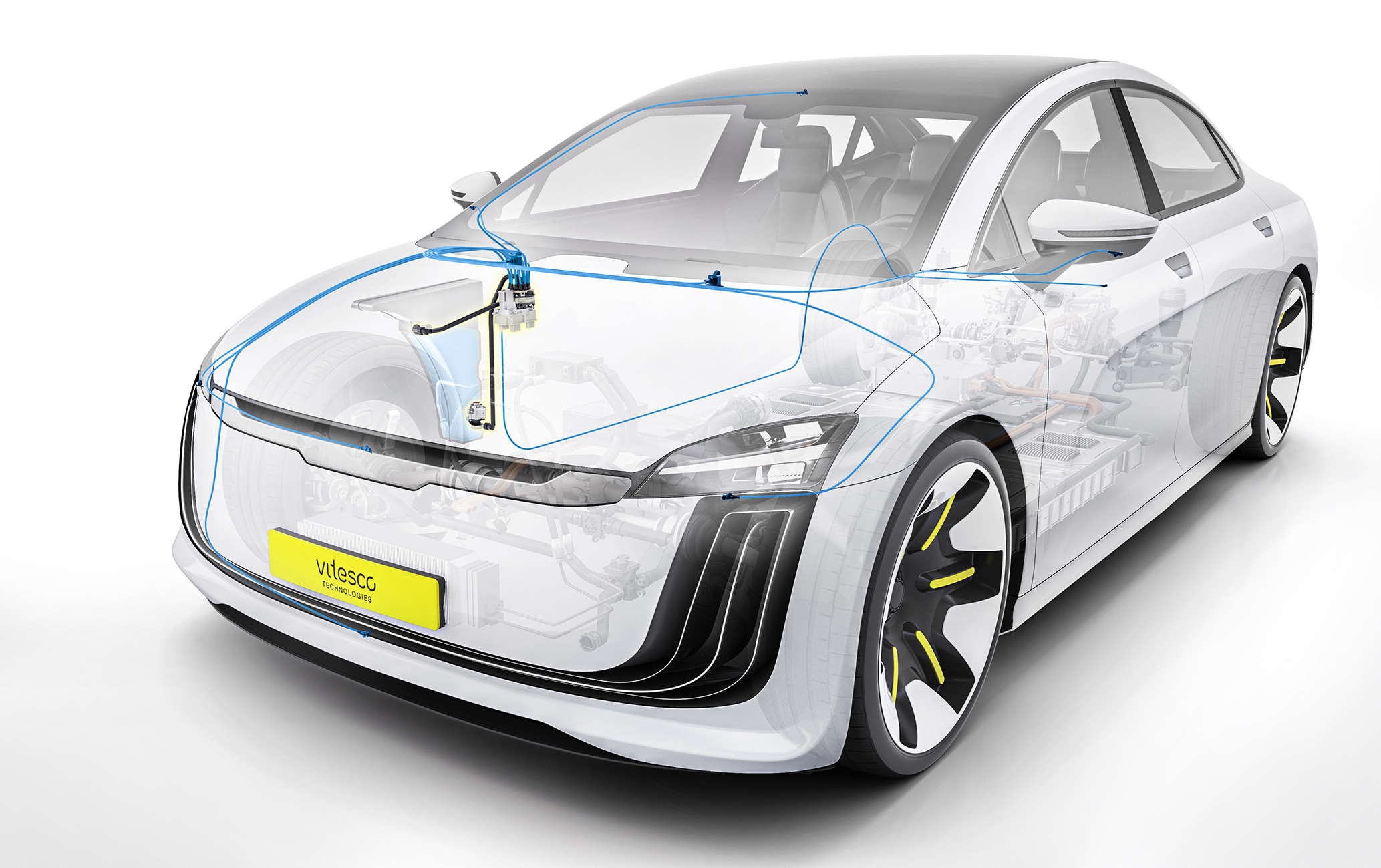

As the fully electric and autonomous vehicles evolve in the world, it's crucial that we ensure these vehicles are operating at optimal performance levels in any environmental condition. One of the main must haves of autonomous vehicle performance is the availability of the equipped cameras and sensors. These cameras and sensors are responsible for collecting data and making decisions on the vehicle's behalf, so it's essential that they always stay in top working condition.

That's where our Advanced Sensor Cleaning System comes in. Our system is designed to thoroughly clean the cameras and sensors of autonomous vehicles using a high-pressure water spray. With a pressure of up to 7 bar, our system removes even the toughest dirt and grime, leaving the cameras and sensors spotless.

A major advantage is its high cleaning efficiency due to our high pressure; we save up to 23 % water compared to lower pressure systems. While other cleaning systems may use excessive amounts of water, our system is designed to be highly efficient, using only the necessary amount of water to get the job done. This not only saves on water usage but also helps to reduce the overall cost and effort of cleaning for the consumer.

We also kept it simple with a single pump and delivery unit. This means that only one pump is needed for distribution, making it easy to install and maintain. This is a major advantage for customers as it reduces the overall cost of the cleaning system and eases the installation as well.

© Vitesco Technologies GmbH (exclusive rights)