.jpg?width=407&resizemode=force)

The Vitesco Technologies Group became part of the Schaeffler Group as of October 1, 2024, due to the merger of Vitesco Technologies Group AG into Schaeffler AG.

Please note: Legal or actual changes since October 1, 2024, are therefore no longer reflected in the content of the website.

As the website is no longer updated, we assume no liability for the content of this website, or the linked websites contained therein. The operators of the linked sites are solely responsible for their content.

Irrespective of this, you can still find the current BPCoC and the General Terms and Conditions of Purchase at Vitesco Technologies - Suppliers (vitesco-technologies.com)

Under the following link you will find the current Schaeffler website:

.jpg?width=407&resizemode=force)

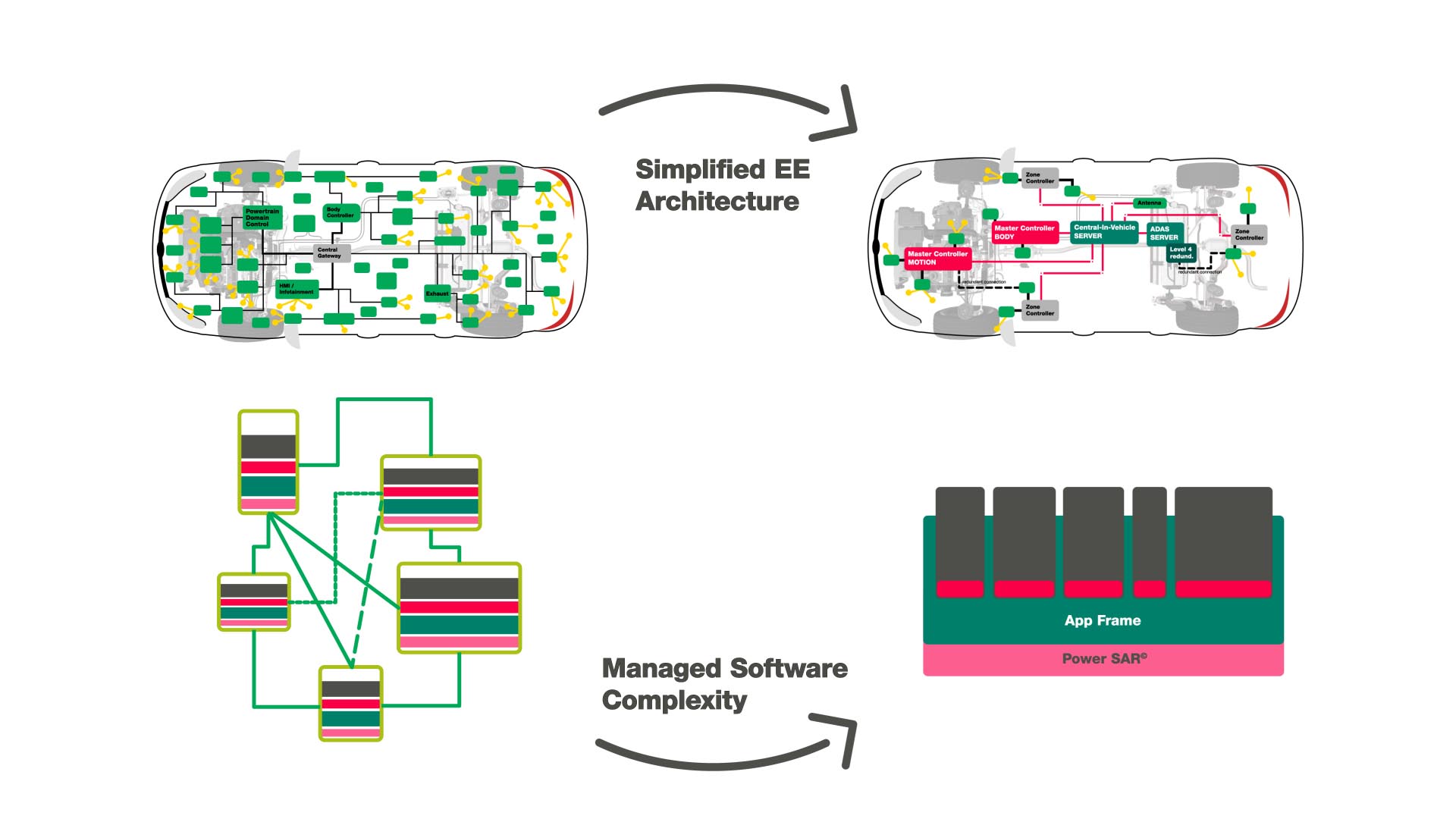

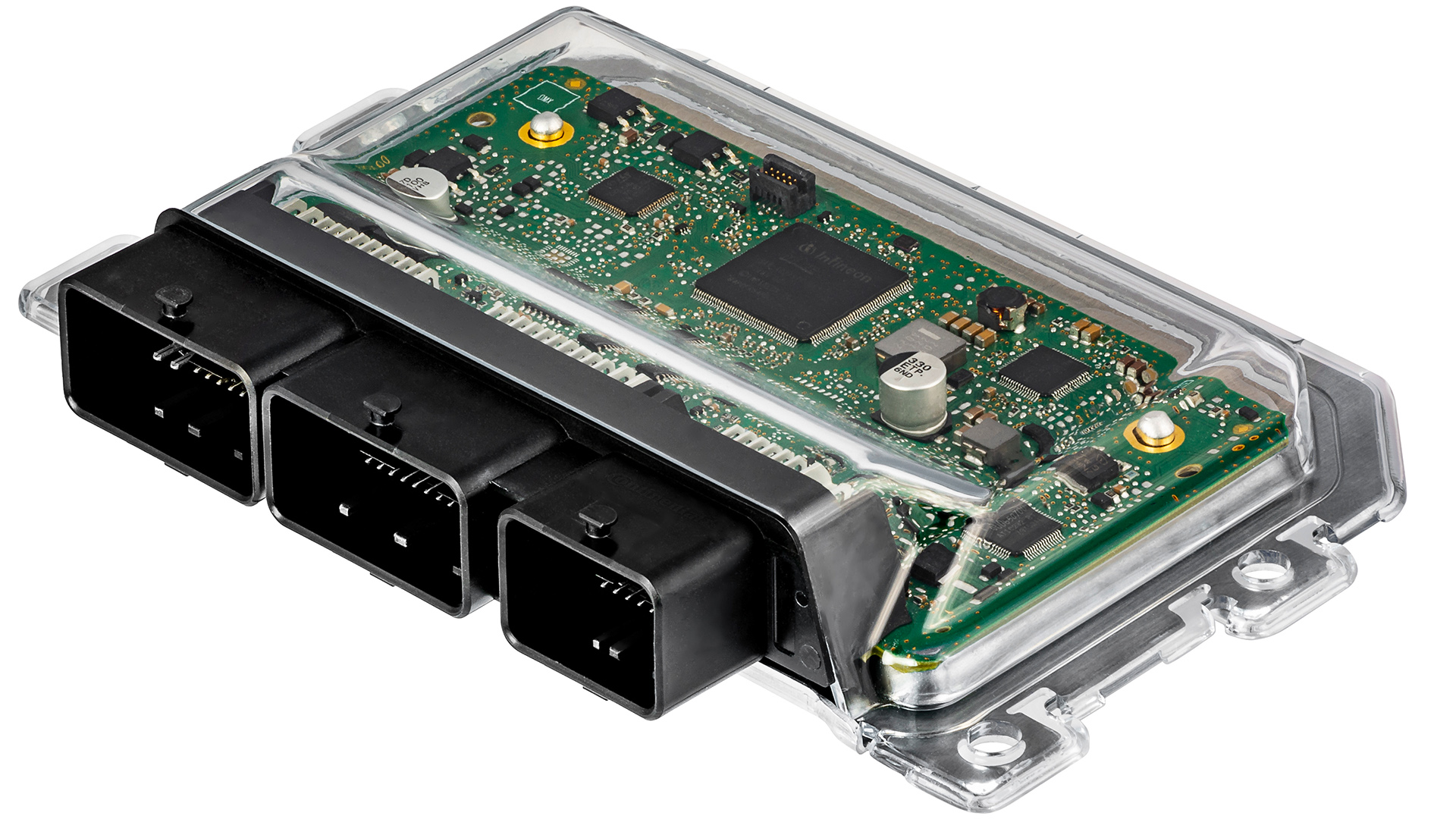

Regensburg (Germany), March 23, 2021. Vitesco Technologies, a leading international supplier of modern drive technologies and electrification solutions, supports a future trend in powertrain control with a new type of controller. The growing number of electrified powertrain topologies plus a constantly growing number of functions are making the current practice of allocating each function to a separate electronic control unit (ECU) overly complex. As a result, the electric and electronic architecture (E/E architecture) of the vehicle powertrain is beginning to change.

A new approach is to replace the many networked ECUs by a single, high-performance controller. This way, the complexity of the connected stand-alone ECUs is transferred to the single controller. For this new E/E architecture, Vitesco Technologies is developing the Master Controller Motion (MCM).

The technological foundation for this up-integration trend is the electronics know-how. This part of the corporate DNA is a legacy from the efficient and extremely reliable engine and transmission ECUs for vehicles with a combustion engine. This legacy of microelectronics expertise from many generations of engine and transmission ECUs is now the indispensable foundation for the oncoming challenges. One thing, however, is new: With the MCM, it is the software that rules what the hardware needs to offer.

Through its architecture, the MCM open-up new possibilities. For instance, the Vitesco Technologies MCM contains a technology that allows integration of individual sub-functions – also over-the-air – very much like an app, thus establishing an individual function mix as per MCM. “Tested embedded apps can be installed individually for each vehicle with this technology. Also, individual apps can be updated at any time, for instance, when a charging standard changes,” according to Hackelsperger.

With this concept, Vitesco Technologies is heralding a new technical era, enabling powertrain control to be kept up-to-date over the car’s complete service life and to even increase its functional content.

The spatial separation of functions is already integrated in the most recent AUTOSAR* release, masterminded by Vitesco Technologies. “Yet, temporal separation is even more demanding and is a technology we’ve developed in-house.”

© Vitesco Technologies GmbH (exclusive rights)

Another thing that is already ongoing at Vitesco Technologies is the development of zone controllers, which execute MCM commands on an intermediate E/E architecture level. Together, both scalable controller types cover the entire scope of future drivetrain E/E architecture requirements in the vehicle.

*AUTOSAR Classic Release R20-11 from November 2020

new era of vehicle motion control

© Vitesco Technologies GmbH (exclusive rights)

The many networked ECUs can be replaced by a single, high-performance controller. This way, the complexity of the connected stand-alone ECUs is transferred to the single controller. For this new E/E architecture, Vitesco Technologies is developing the Master Controller Motion (MCM).

© Vitesco Technologies GmbH (exclusive rights)

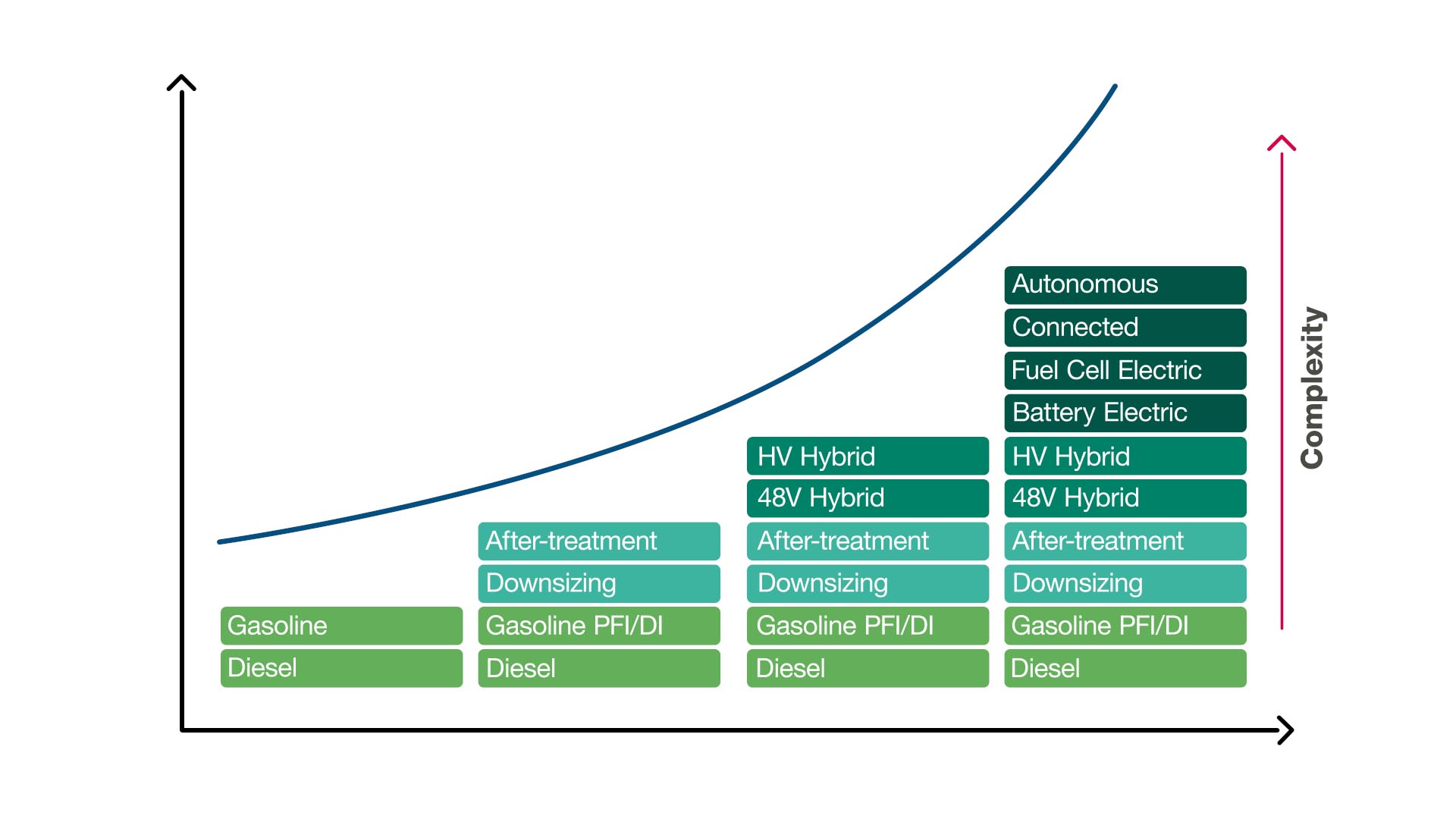

The electrification trend leads to an increasing number of electronic control units in the vehicle.

© Vitesco Technologies GmbH (exclusive rights)

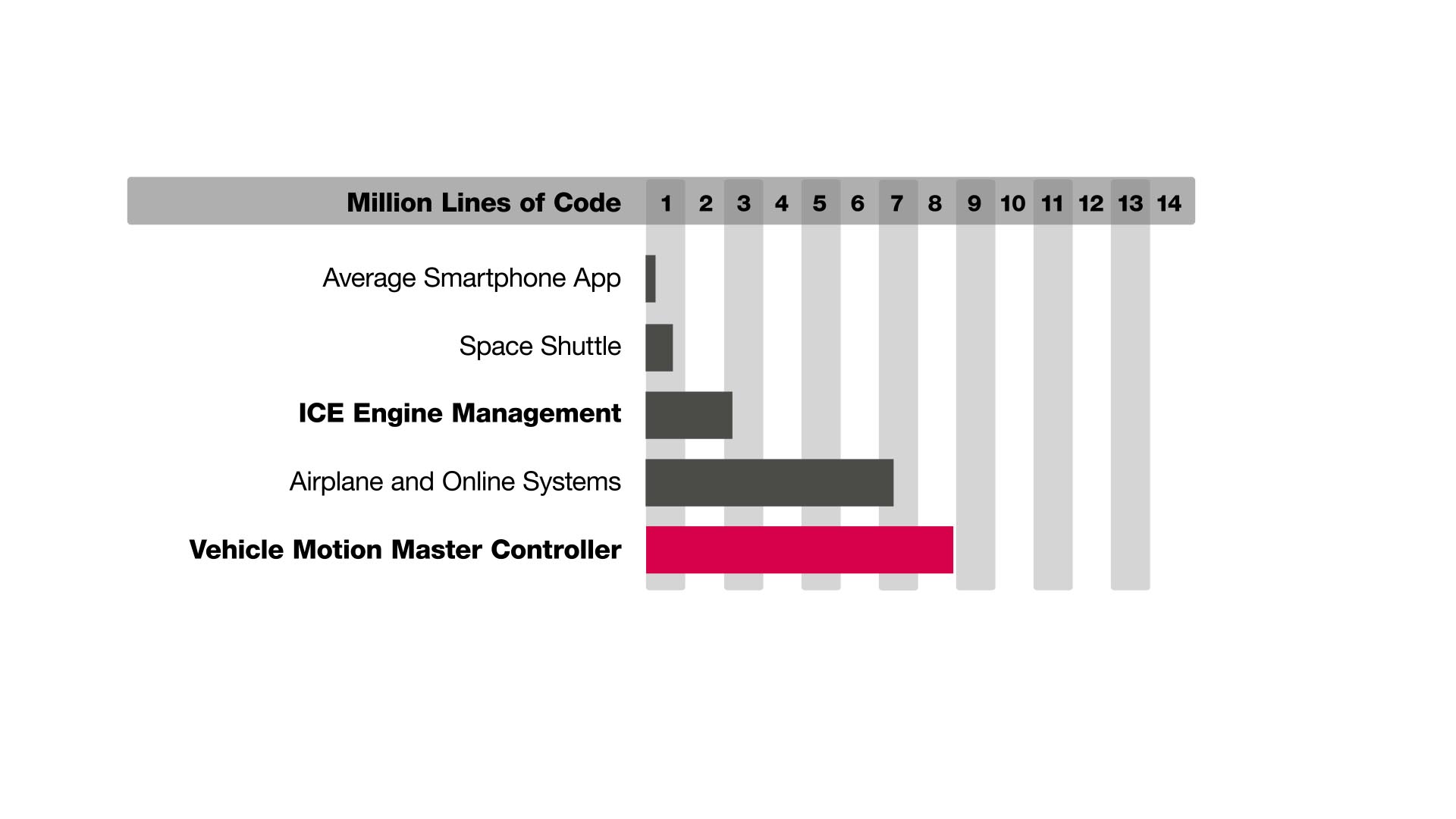

Often, the software consists of million lines of code and is very complex.

© Vitesco Technologies GmbH (exclusive rights)

The E/E architecture of the drive faces transformation. The new approach combines the individual controllers in one very powerful control device (UP integration) – the Master Control Motion (MCM).

© Vitesco Technologies GmbH (exclusive rights)

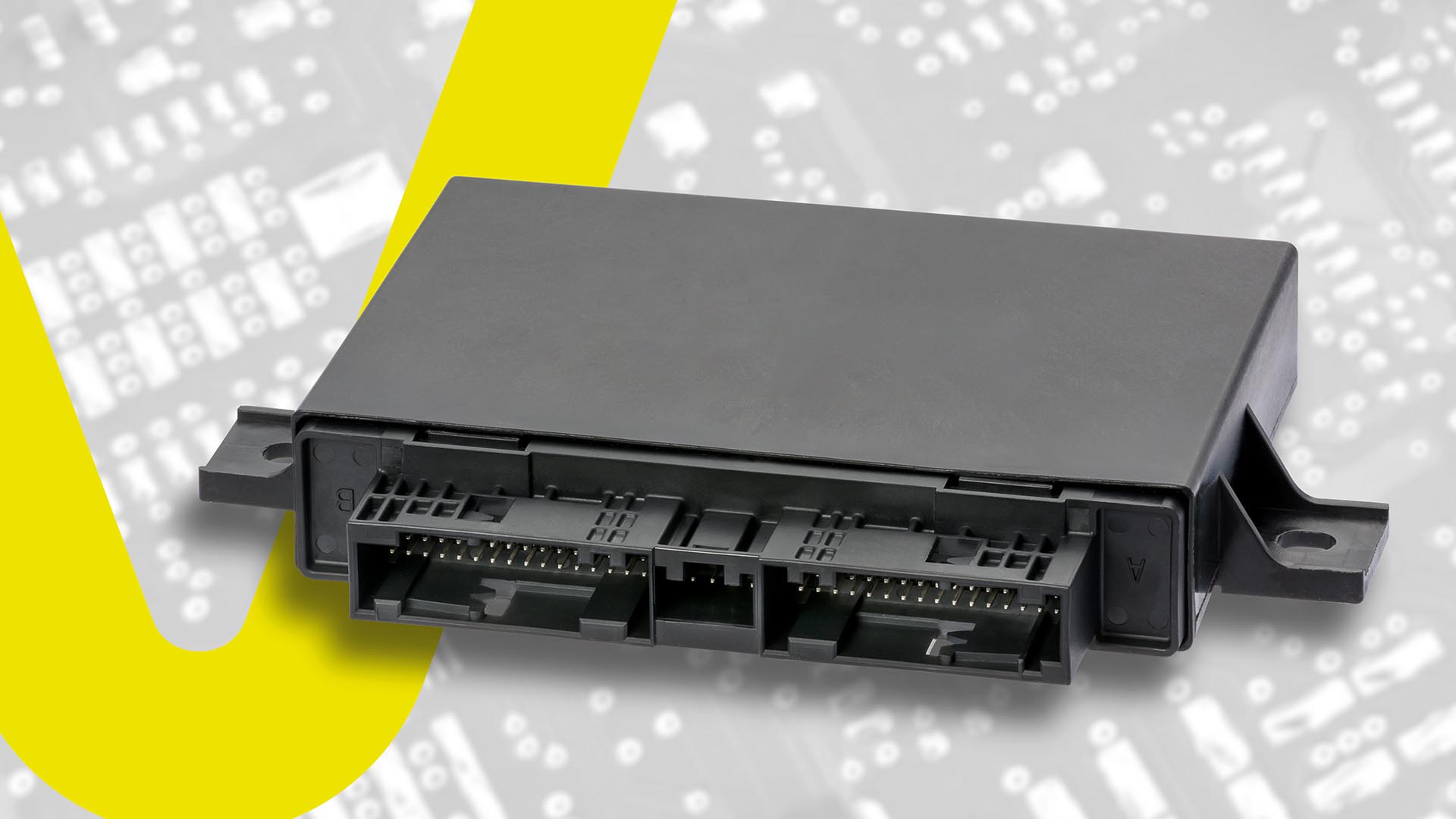

The Master Controller Motion enables the OEM to reduce the complex vehicle architecture and save costs. This is the future of powertrain.

© Vitesco Technologies GmbH (exclusive rights)