.jpg?width=407&resizemode=force)

The Vitesco Technologies Group became part of the Schaeffler Group as of October 1, 2024, due to the merger of Vitesco Technologies Group AG into Schaeffler AG.

Please note: Legal or actual changes since October 1, 2024, are therefore no longer reflected in the content of the website.

As the website is no longer updated, we assume no liability for the content of this website, or the linked websites contained therein. The operators of the linked sites are solely responsible for their content.

Irrespective of this, you can still find the current BPCoC and the General Terms and Conditions of Purchase at Vitesco Technologies - Suppliers (vitesco-technologies.com)

Under the following link you will find the current Schaeffler website:

.jpg?width=407&resizemode=force)

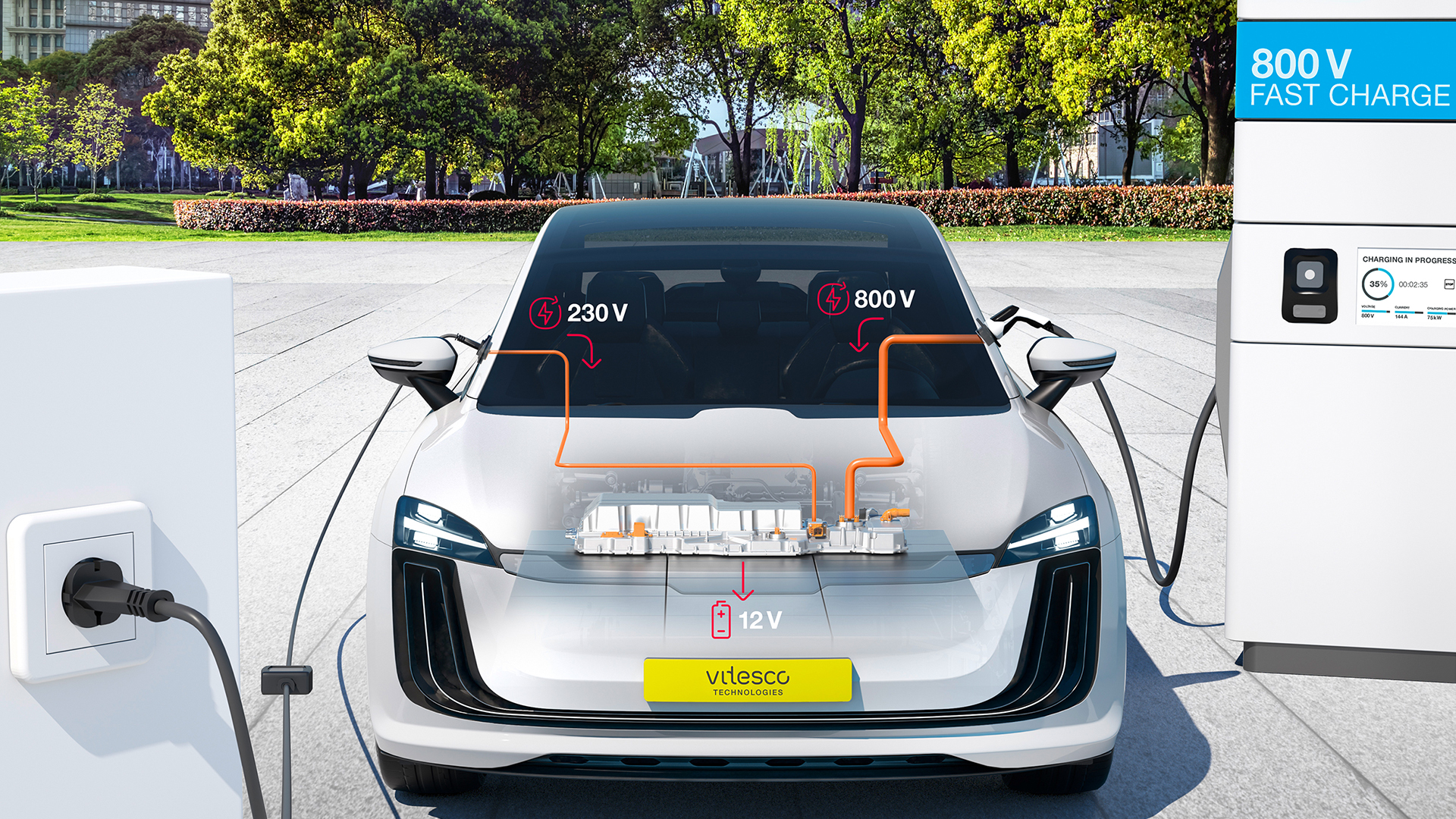

Regensburg, Germany. March 23, 2021. The future car is electric. As all electrified vehicles require high voltage electronics, the rapidly growing market of EVs and hybrids makes power electronics a very attractive growth opportunity. Vitesco Technologies has the full portfolio of solutions to serve the demanding market. Charging an electrified vehicle is one key application area of high voltage electronics.

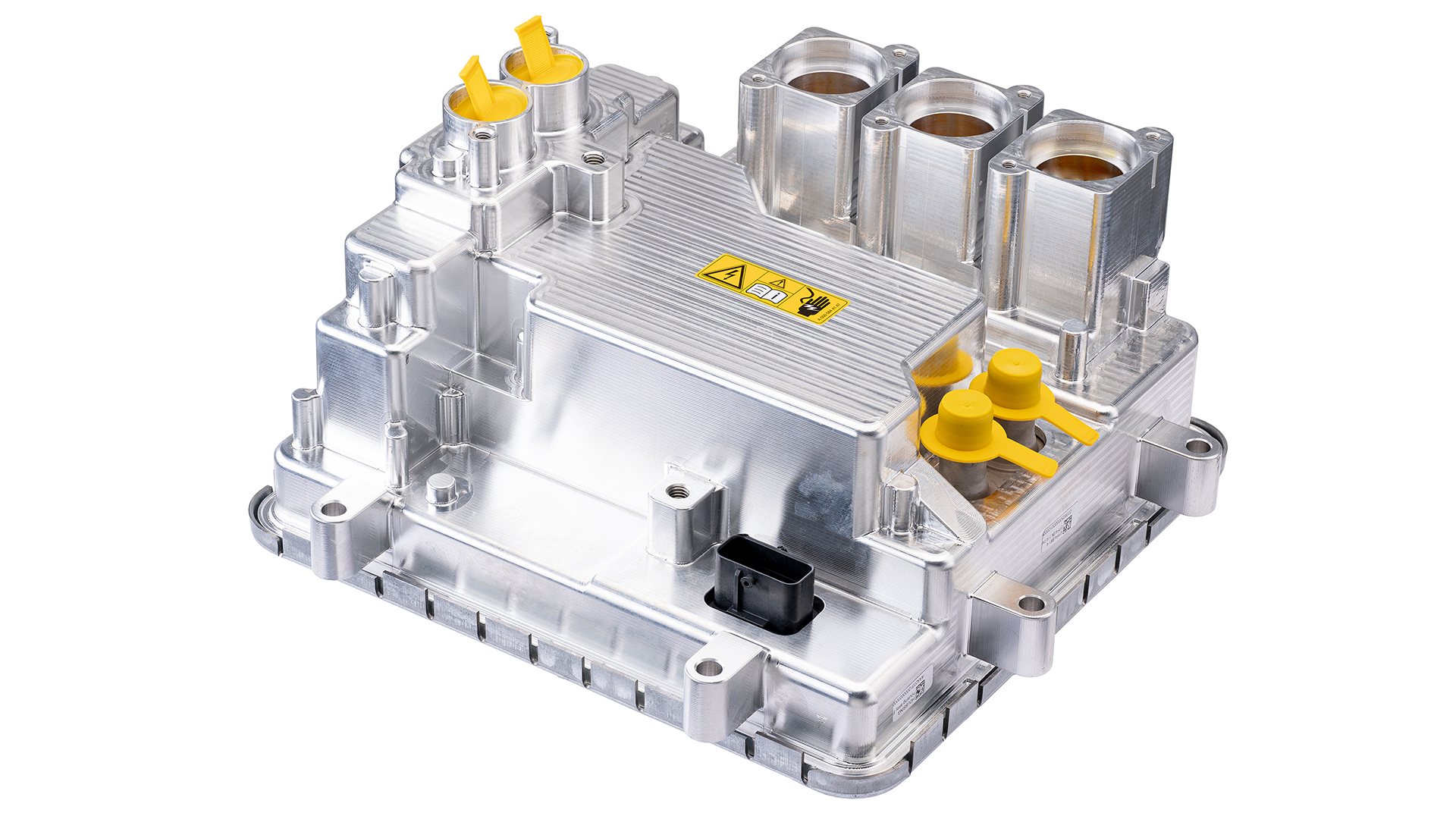

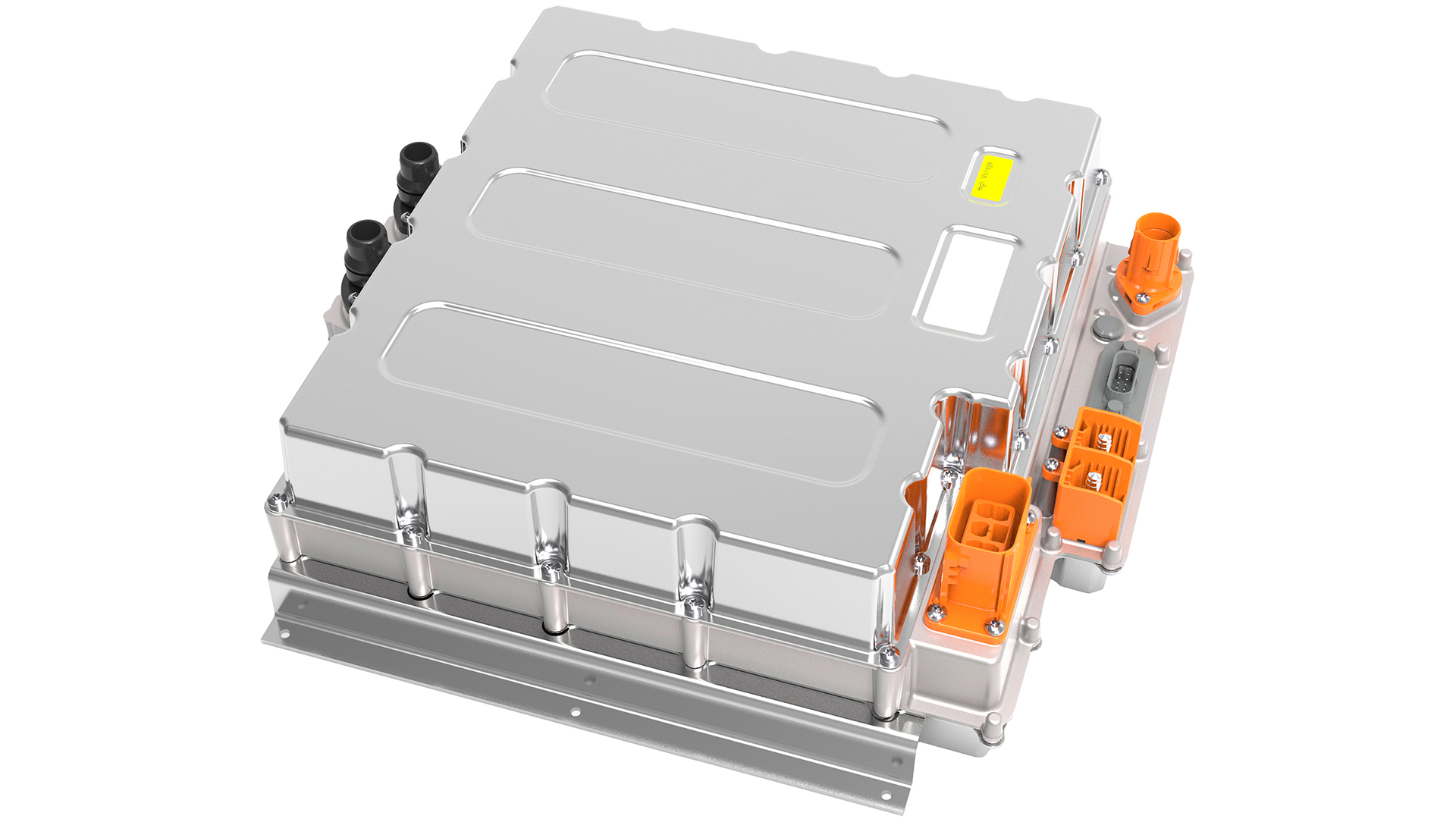

Vitesco Technologies’ new High-Voltage (HV) Box combines functions such as on-board charging, DC-DC energy conversion and in-vehicle power distribution into a single electronic hub. The hub greatly simplifies the car’s electrical and electronic (E/E) landscape. The Battery Management System (BMS) protects the battery, the most expensive component of an electric car, from misuse and damage, prolongs battery life and ensures that the battery is always ready for use. Together, the HV Box and BMS play a central role in maximizing the energy efficiency of EVs and PHEVs.

Charging from the grid can be done in one of two ways. The first is “normal” charging using alternating current (AC) at up to 22 kW of power. The second method is “fast” charging with direct current (DC) energy at up to 350 kW of power, via a specially equipped high-power DC charging station which delivers up to 30 km of driving range per minute of charging.

© Vitesco Technologies GmbH (exclusive rights)

A prominent part of the HV Box is the On-Board Charger, which converts AC power from the electric grid to DC form, for use by the BMS. The BMS acts as the brain of the battery by managing the charging and discharging of individual battery cells via cell balancing. Further, it provides very precise diagnostics and ensures electrical safety under all circumstances. The BMS contains software algorithms which continuously monitor, diagnose and correct undesirable operating conditions to maximize driving range and battery lifetime.

Handling the high energy flows in an electric car requires special power electronics which operate in 400 V and even 800 V power-nets. These electronics tend to be large, heavy and complex. Current electric car models contain distributed HV electronics – i.e. separate devices for each energy conversion function. The distributed devices not only carry more direct weight and cost, but they also drive the need for more heavy wiring to connect those separate devices. Vitesco Technologies has taken a step towards making e-mobility more affordable by integrating closely related energy conversion functions together in the HV Box and BMS.

Despite the high integration provided by the HV Box, Vitesco Technologies is still able to offer a range of AC charging power levels from 7 kW to 22 kW, compatibility with global electric grids, 400 V or 800 V power-nets, DC-DC power ranges and more. The HV Box and BMS are the result of modular designs and expert system integration knowhow in electronics, mechanics and software, which are at the heart of Vitesco Technologies’ DNA.

Since established carmakers have diverse vehicle fleets, there is no ‘one size fits all’. Moreover, every carmaker has their own strategy for E/E integration, in-vehicle voltages, power levels and software functions. Vitesco Technologies’ HV Box and BMS solutions contain the modularity to support many car makers’ strategies. Even within the platforms of a single car maker, Vitesco Technologies covers the needs of the entire fleet, from A segment to SUVs.

The HV Box and the BMS also ensure safe transfer of energy to protect the car’s operator against electric shock. For instance, the BMS contains the intelligence to carefully manage the flow of high current to the battery, to prevent electrical shock or overheating. In the event of a crash, the BMS also triggers the electrical isolation of the battery from the rest of the car.

The modular and scalable concept is a big step forward in making electro-mobility affordable. The HV Box and BMS greatly reduce complexity and help carmakers to reduce the size, weight and cost of electronics and wiring inside the car. Our solutions play a central role in making electric driving safe, affordable and environmentally sustainable.

Charging from the grid can be done in one of two ways. The first is “normal” charging using alternating current (AC) at up to 22 kW of power. The second method is “fast” charging with direct current (DC) energy at up to 350 kW of power.

© Vitesco Technologies GmbH (exclusive rights)

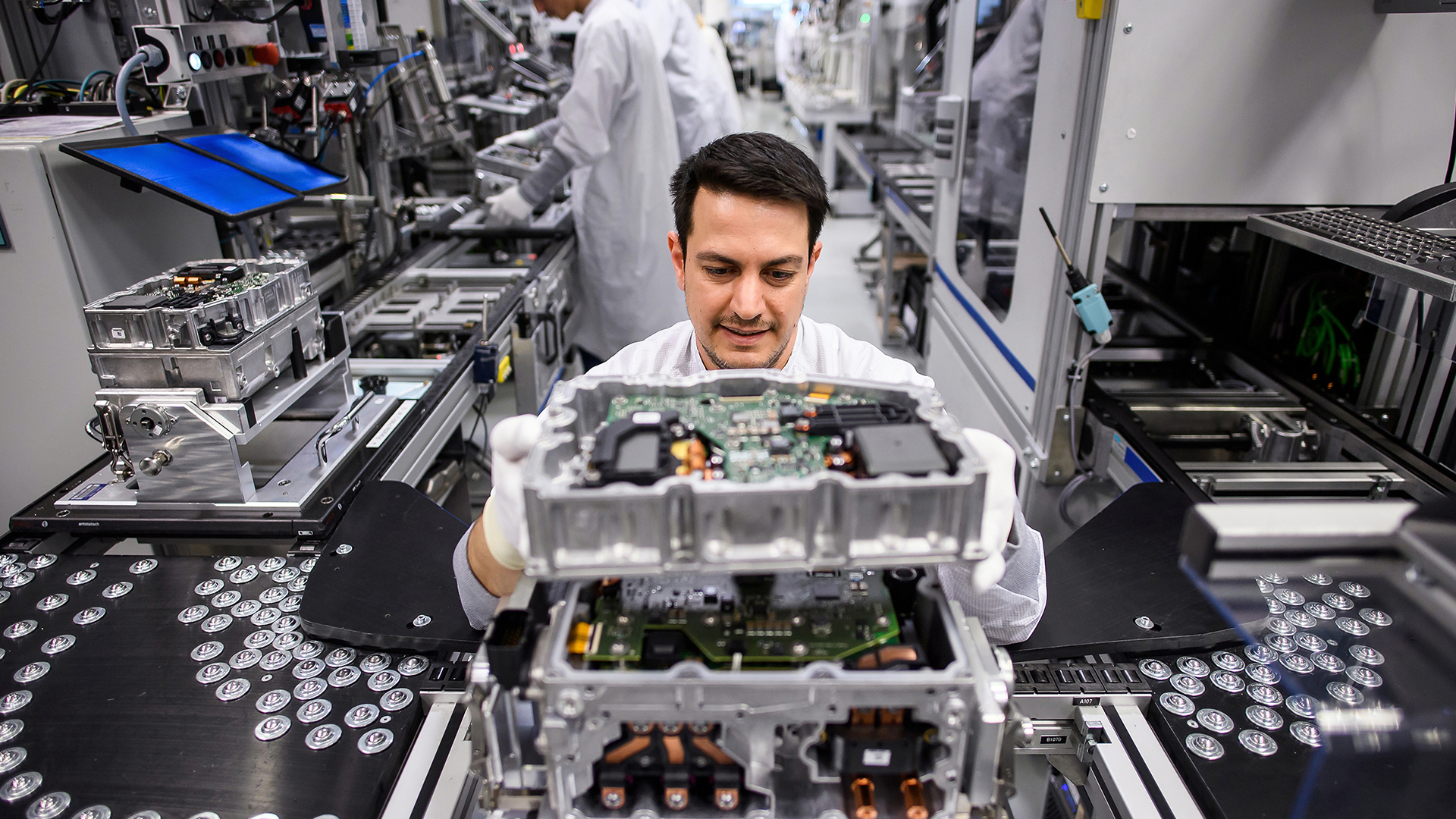

Production of power electronics at Vitesco Technologies

© Vitesco Technologies GmbH (exclusive rights)

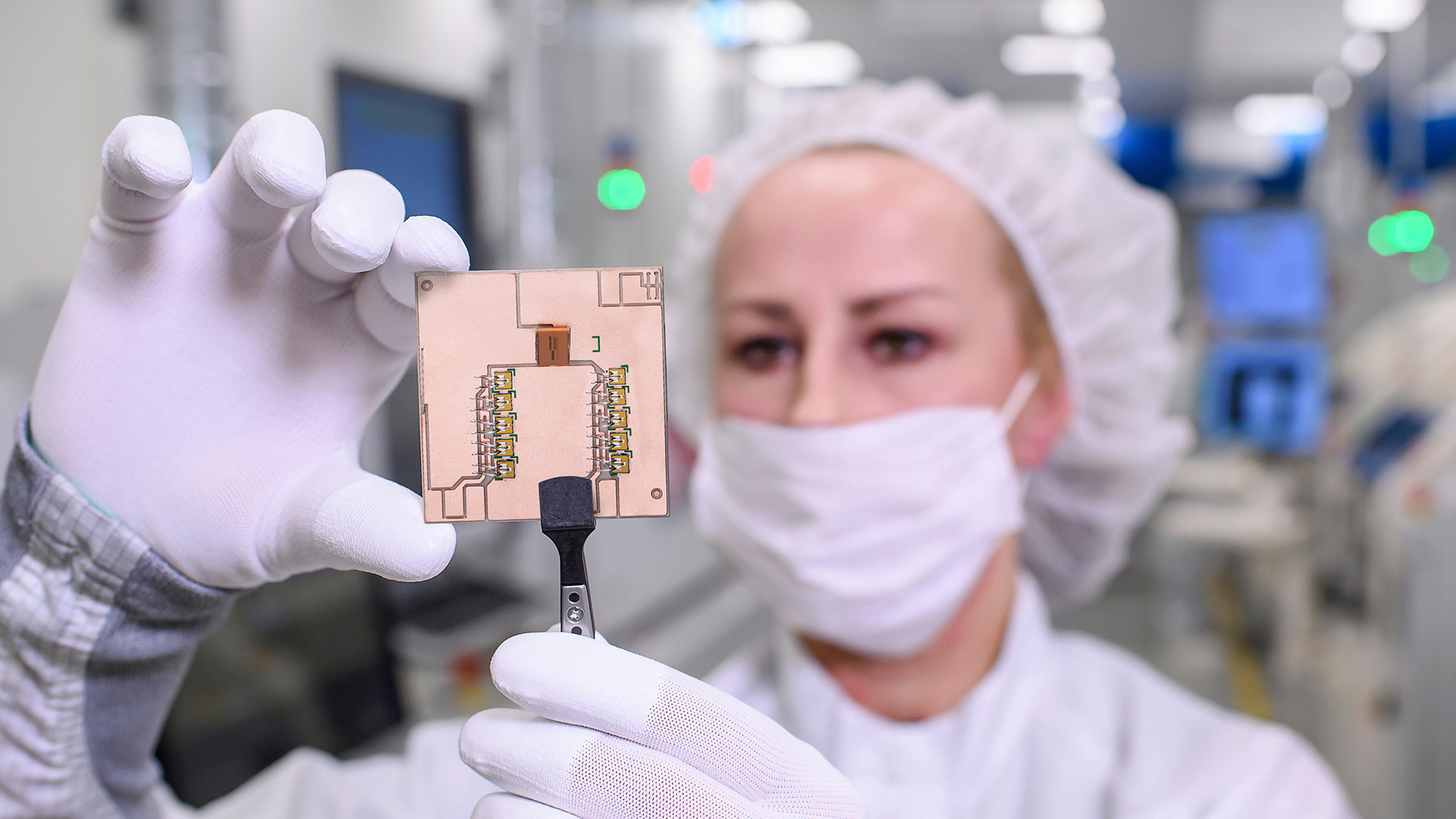

The next step towards efficient electromobility: Vitesco Technologies cooperates with ROHM in the field of SiC technology.

© Vitesco Technologies GmbH (exclusive rights)

Next generation inverter platform.

© Vitesco Technologies GmbH (exclusive rights)

Vitesco Technologies’ new High-Voltage (HV) Box combines functions such as on-board charging, DC-DC energy conversion and in-vehicle power distribution into a single electronic hub, which greatly simplifies the car’s electrical and electronic (E/E) landscape.

© Vitesco Technologies GmbH (exclusive rights)