.jpg?width=407&resizemode=force)

The Vitesco Technologies Group became part of the Schaeffler Group as of October 1, 2024, due to the merger of Vitesco Technologies Group AG into Schaeffler AG.

Please note: Legal or actual changes since October 1, 2024, are therefore no longer reflected in the content of the website.

As the website is no longer updated, we assume no liability for the content of this website, or the linked websites contained therein. The operators of the linked sites are solely responsible for their content.

Irrespective of this, you can still find the current BPCoC and the General Terms and Conditions of Purchase at Vitesco Technologies - Suppliers (vitesco-technologies.com)

Under the following link you will find the current Schaeffler website:

.jpg?width=407&resizemode=force)

Debrecen (Hungary). February 26, 2021. After just two years of construction, the newest Vitesco Technologies plant in Debrecen, Hungary, went now into operation. In the future, the drive specialist will produce high-tech electronics and transmission sensor technology for all types of drive systems in an area of around 7,000 square meters – from all-electric vehicles to plug-in hybrid vehicles and electrified combustion engines. Vitesco Technologies is thus further expanding its international presence in order to be able to meet the global demand for clean drive solutions. The company has invested a total of around €100 million in the plant.

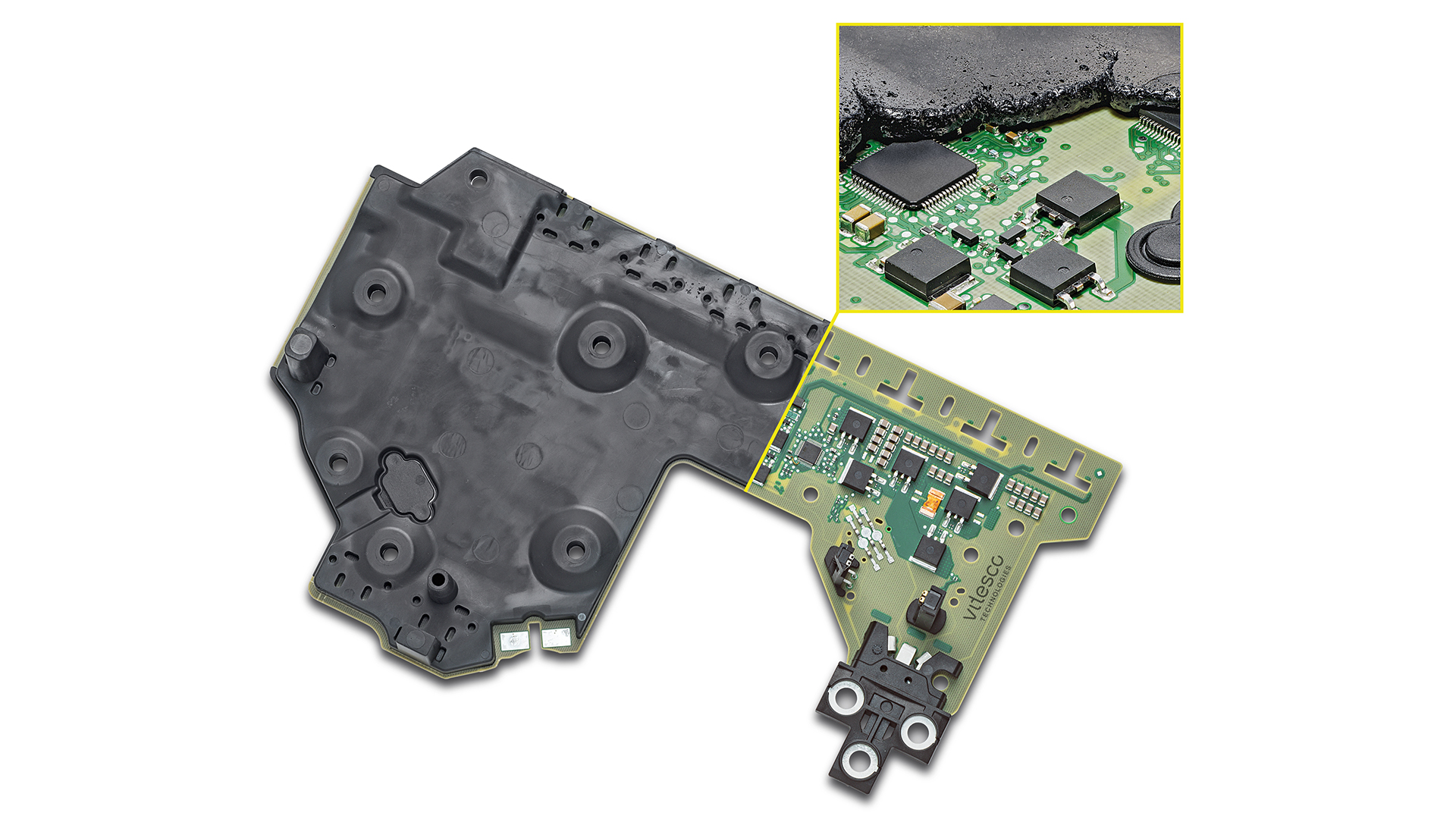

One first large-scale production to be manufactured in Debrecen, is the transmission control unit with overmolding technology. Compared with conventional devices, it is not only more robust and lighter, but it also requires considerably fewer production steps. This is thanks to an innovative process known as overmolding. Here, the electronic components, which are arranged on a printed circuit board as in classic control units, are embedded in plastic. Vitesco Technologies uses new, high-precision injection molding processes as well as new, particularly resistant plastics.

In addition to the electronic control systems, the production plant in Debrecen also covers further components in the fields of electrification and electric mobility, including 48-volt belt starter generators for mild hybrids.

Vitesco Technologies is also striving for LEED certification for the new plant: Leadership in Energy and Environmental Design (LEED) is a system for classifying ecological construction, developed by the US Green Building Council in 1998. The internationally recognized gold category is awarded exclusively to projects that meet strict requirements and standards for environmentally friendly, resource-efficient and sustainable construction. For example, by having its own solar panels for energy generation and consistent recycling. In addition, the facility has fully integrated building and energy management systems which control the building parameters based on real-time requirements. In May 2019, the design and structure were pre-certified. Final certification is intended by the end of March 2021.

In line with the Industry 4.0 concept, the plant is flexibly designed with autonomous transport robots in the production hall, an intelligent warehouse management system, computer-assisted maintenance systems, and other automated building functions. All new employees complete a tailor-made mentoring and qualification program in the company’s own training center within the first six months.

At its new plant in Debrecen, Hungary, Vitesco Technologies produces high-tech electronics and transmission sensor technology for all types of drive systems in an area of around 7,000 square meters – from all-electric vehicles to plug-in hybrid vehicles and electrified combustion engines.

© Vitesco Technologies GmbH (exclusive rights)

“This high-tech plant is already showing what the factory of tomorrow will look like – intelligent, lean and green,” explains Dr. Hans-Jürgen Braun, Head of Operations

© Vitesco Technologies GmbH (exclusive rights)

One first large-scale production to be manufactured in Debrecen, is a control unit with the innovative overmolding technology.

© Vitesco Technologies GmbH (exclusive rights)

The Overmolding technology not only makes control units more robust and lighter, it also requires considerably fewer production steps.

© Vitesco Technologies GmbH (exclusive rights)