.jpg?width=407&resizemode=force)

The Vitesco Technologies Group became part of the Schaeffler Group as of October 1, 2024, due to the merger of Vitesco Technologies Group AG into Schaeffler AG.

Please note: Legal or actual changes since October 1, 2024, are therefore no longer reflected in the content of the website.

As the website is no longer updated, we assume no liability for the content of this website, or the linked websites contained therein. The operators of the linked sites are solely responsible for their content.

Irrespective of this, you can still find the current BPCoC and the General Terms and Conditions of Purchase at Vitesco Technologies - Suppliers (vitesco-technologies.com)

Under the following link you will find the current Schaeffler website:

.jpg?width=407&resizemode=force)

Debrecen, June 24, 2021. Today, the Debrecen plant of Vitesco Technologies, a leading international provider of modern drivetrain technologies and solutions for e-mobility, has been officially opened. The 7,000 square metre plant, which is already in operation since February, further increases the company's international presence to meet the growing demand for clean propulsion solutions. The event was attended in person by Péter Szijjártó, Minister of Foreign Affairs and Trade, Dr. László Pósán, Member of Parliament, Dr. László Papp, Mayor of Debrecen, and Dr. Hans-Jürgen Braun, Senior Vice President of Operations at Vitesco Technologies.

Lukas Juranek, Managing Director of Vitesco Technologies Hungary Kft., said in his welcoming speech: "We have created a high-tech smart factory that meets the needs of energy-efficient green investments. In Debrecen, Vitesco Technologies not only manufactures high-quality products for clean and sustainable mobility, but also offers excellent career opportunities for employees in the region."

In his speech, Dr. László Pósán, Member of Parliament for the region, recalled that “Debrecen is a city that has been open to innovation for centuries, while also being tied to its traditions. That is why Vitesco Technologies has found an ideal partner in Debrecen, which, like Vitesco Technologies, has ambitious and forward-looking plans. The new factory offers the opportunity for employees to acquire state-of-the-art knowledge and learn about the latest technologies locally.”

Péter Szijjártó, Minister of Foreign Affairs and Trade, highlighted that “the automotive industry is the backbone of the Hungarian economy. This is why it is important for the government to maintain this role in the new era of the automotive industry. The new Vitesco Technologies plant in Debrecen plays a prominent role in this.”

With the opening of its new factory in Debrecen, Vitesco Technologies will create roundabout 450 jobs in the city by mid-2022. The plant represents an investment of around €100 million euro and produces high-tech automotive electronics and transmission controls. It will also cover a range of other areas of electromobility and vehicle electrification, such as 48-volt starter generators for mild hybrids. The plant is a member of the international RE100 initiative and uses 100 percent renewable electricity for its operations.

“This high-tech plant is already showing what the factory of tomorrow will look like – intelligent, lean and green,” explains Dr. Hans-Jürgen Braun, Head of Operations

© Vitesco Technologies GmbH (exclusive rights)

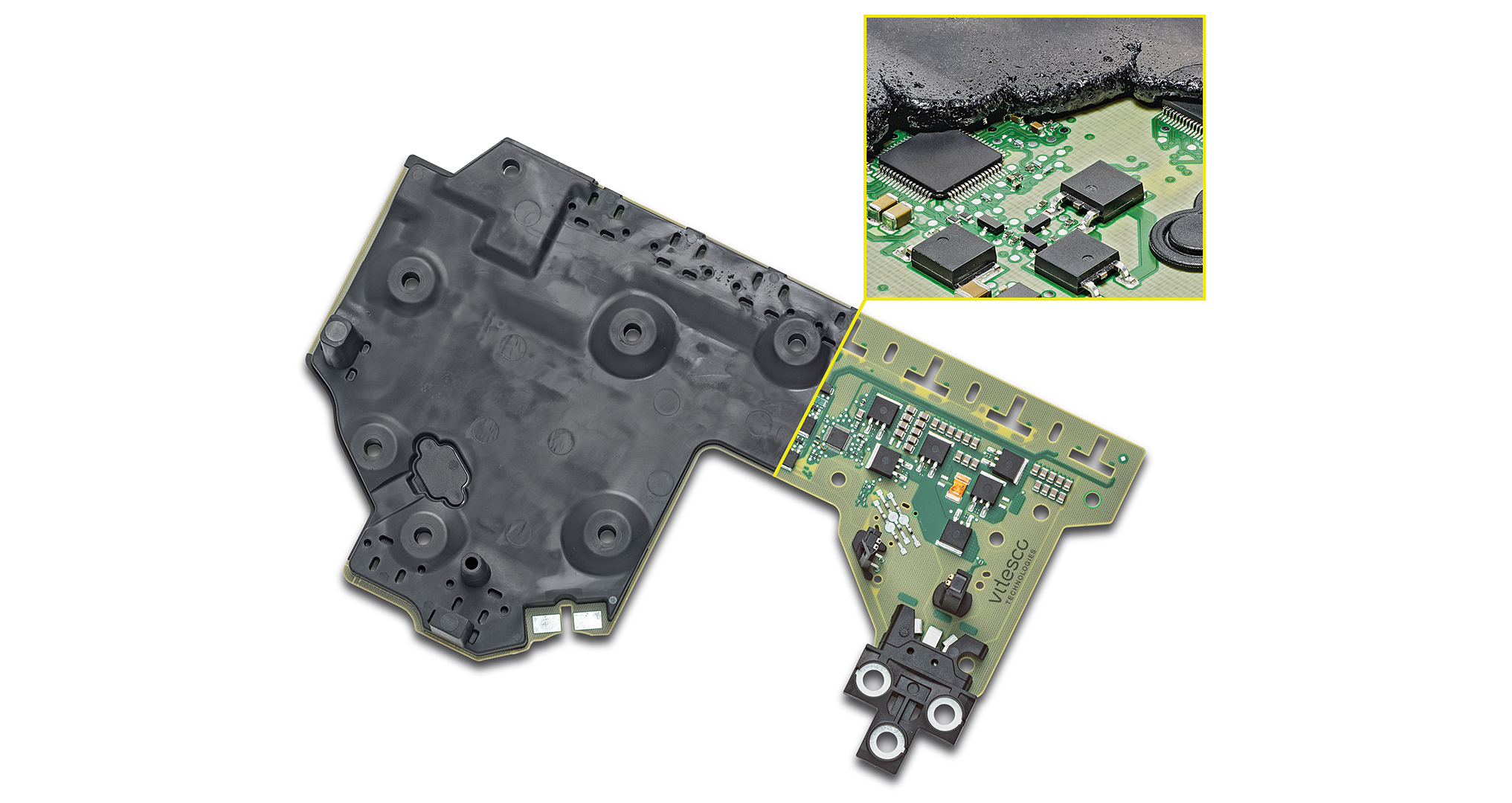

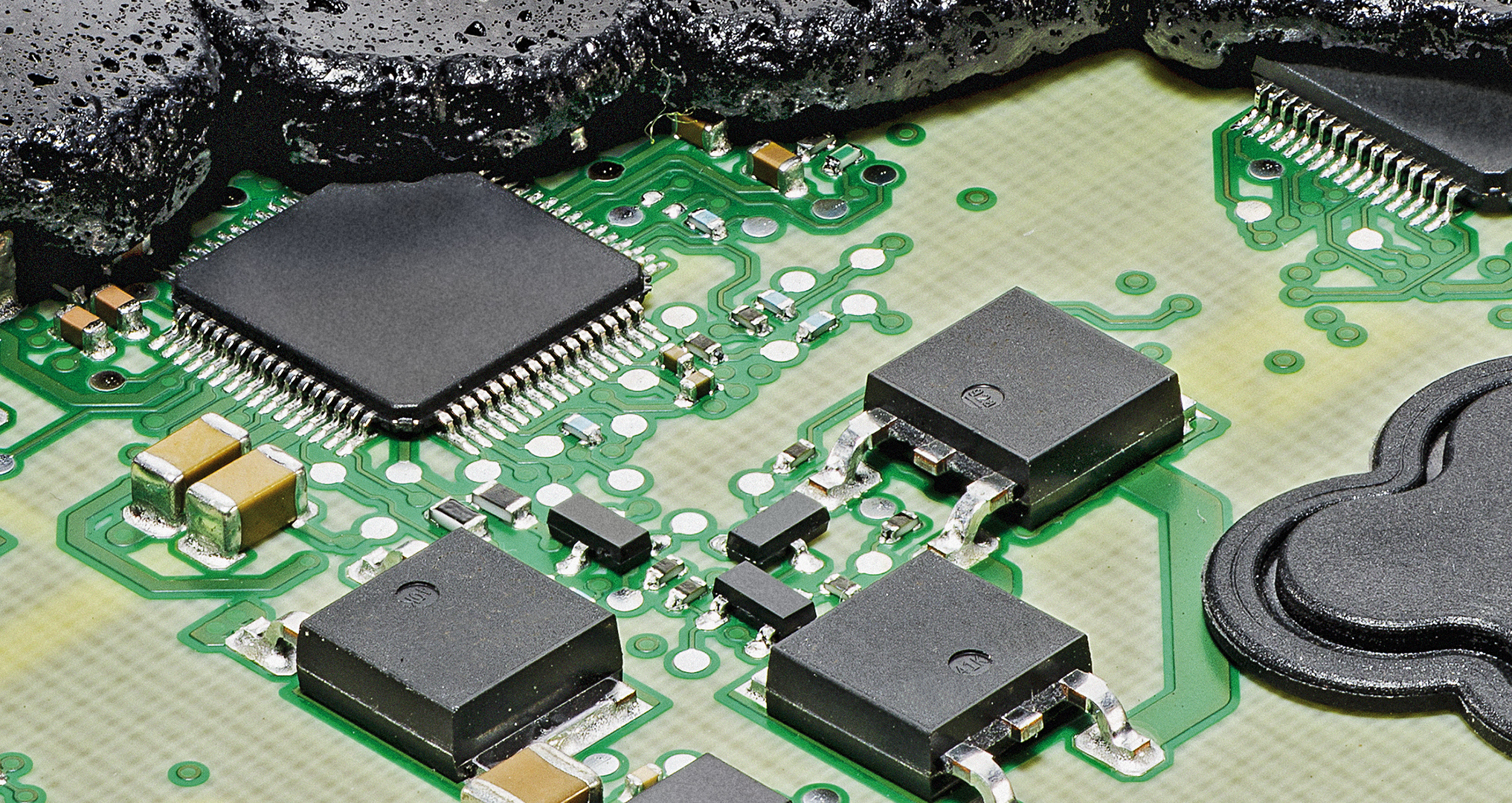

At its new plant in Debrecen, Hungary, Vitesco Technologies produces high-tech electronics and transmission sensor technology for all types of drive systems in an area of around 7,000 square meters – from all-electric vehicles to plug-in hybrid vehicles and electrified combustion engines.

© Vitesco Technologies GmbH (exclusive rights)

One first large-scale production to be manufactured in Debrecen, is a control unit with the innovative overmolding technology.

© Vitesco Technologies GmbH (exclusive rights)

The Overmolding technology not only makes control units more robust and lighter, it also requires considerably fewer production steps.

© Vitesco Technologies GmbH (exclusive rights)