.jpg?width=407&resizemode=force)

The Vitesco Technologies Group became part of the Schaeffler Group as of October 1, 2024, due to the merger of Vitesco Technologies Group AG into Schaeffler AG.

Please note: Legal or actual changes since October 1, 2024, are therefore no longer reflected in the content of the website.

As the website is no longer updated, we assume no liability for the content of this website, or the linked websites contained therein. The operators of the linked sites are solely responsible for their content.

Irrespective of this, you can still find the current BPCoC and the General Terms and Conditions of Purchase at Vitesco Technologies - Suppliers (vitesco-technologies.com)

Under the following link you will find the current Schaeffler website:

.jpg?width=407&resizemode=force)

Regensburg, Nuremberg (Germany), Debrecen (Hungary). October 5, 2020. With a new, globally unique manufacturing process for a transmission control unit, Vitesco Technologies, a leading international manufacturer of modern drive technologies and electrification solutions, is once again underscoring its expertise and innovative strength in the field of high-tech electronics.

In comparison with conventional control units, the new product, known as overmolding control electronics, excels with around 45% less weight, greater robustness and significantly fewer production stages. This results in clear cost advantages.

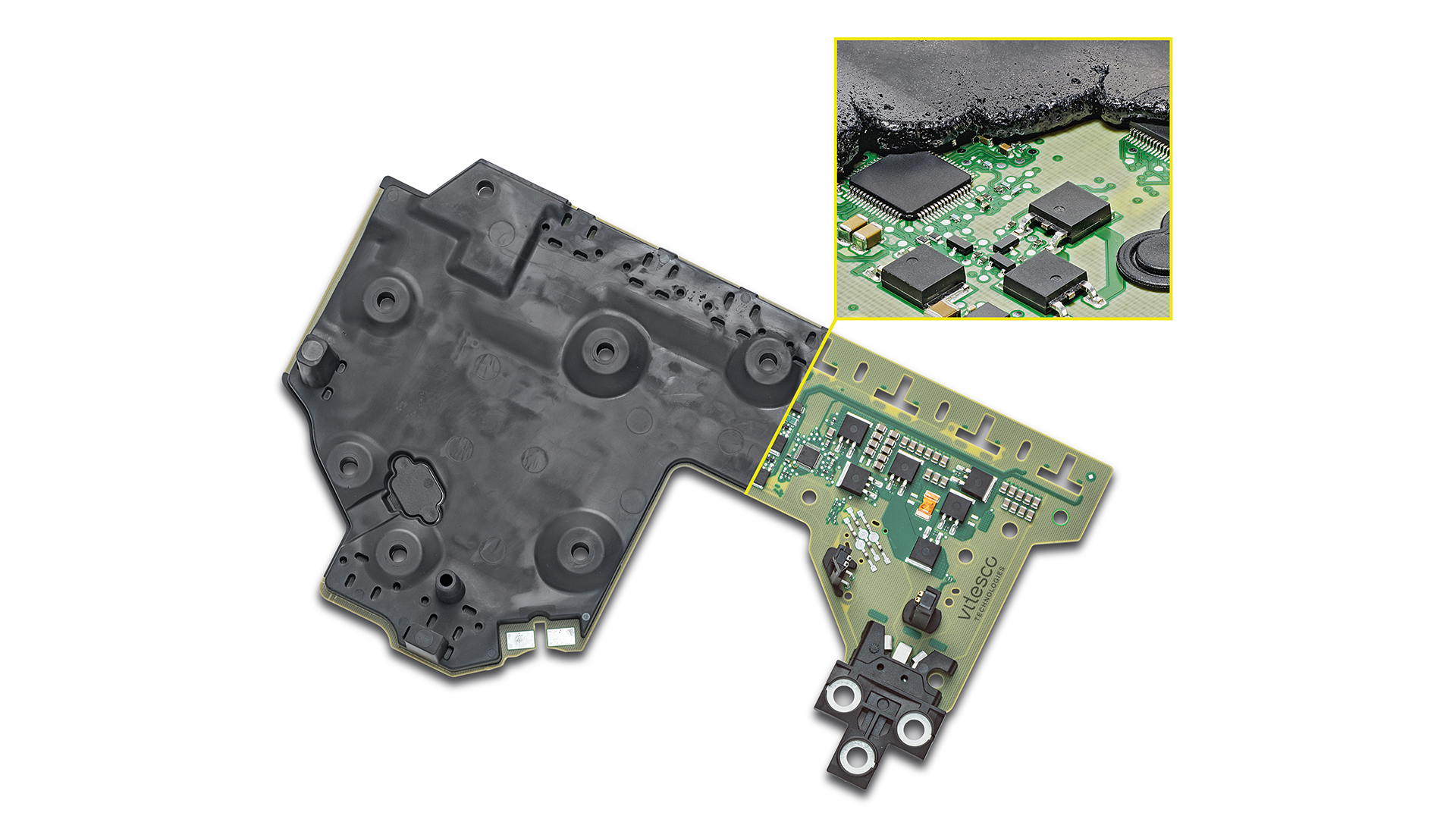

In the conventional design of an electronic control unit, the electronics are located within a housing. By contrast, in an overmolding electronic control unit, the electronic components, which are arranged on a printed circuit board as is normally the case, are completely embedded in plastic. New, high-precision injection molding processes as well as new, particularly resistant plastics enable worldwide serial automobile production of this type of electronic control unit by Vitesco Technologies for the very first time.

The overmolding manufacturing process offers several advantages at once. Firstly, on account of the extreme robustness of the components - since the sensitive high-tech components are completely enclosed in plastic – they can easily withstand even strong vibrations. Secondly, an overmolding component is not only lighter than a comparable electronic control unit in a conventional housing, but also significantly flatter. The transmission control unit developed by Vitesco Technologies is currently the flattest transmission control unit on the market with a thickness of only seven millimeters. By way of comparison, the control unit used up to now was 1.5 centimeters thick. The difference definitely plays a decisive role, as the electronic control unit is screwed directly into the transmission, and installation space is very limited there, in fact every millimeter counts. Another advantage is that an overmolding component can be produced using considerably fewer production stages than a housed electronic control unit. The new technology thus reduces complexity and is also considerably more cost-effective.

The new overmolding electronic control unit has been produced in Nuremberg since spring 2020 and has already been used in large-scale production by a German car manufacturer in various vehicle types with rear wheel drive and automatic transmission. As of the beginning of 2021, Vitesco Technologies will also be producing the overmolding electronic control in the new plant in Debrecen, Hungary, which is currently being completed. Thanks to the high degree of flexibility and extensive technical expertise in the global plant network, Vitesco Technologies is in a position to roll out such state-of-the-art production technologies on a large scale.

With the technological leap that the new manufacturing process enables, Vitesco Technologies is once again driving the trend towards greater integration, more efficient processes and more sustainable technologies. This means that overmolding expertise is a further building block in driving forward the electrification of the drive system and thus sustainable mobility.

The new overmolding control electronics excels with around 45% less weight, greater robustness and significantly fewer production stages.

© Vitesco Technologies GmbH (exclusive rights)

In an overmolding electronic control unit, the electronic components, which are arranged on a printed circuit board as is normally the case, are completely embedded in plastic.

© Vitesco Technologies GmbH (exclusive rights)