.jpg?width=407&resizemode=force)

The Vitesco Technologies Group became part of the Schaeffler Group as of October 1, 2024, due to the merger of Vitesco Technologies Group AG into Schaeffler AG.

Please note: Legal or actual changes since October 1, 2024, are therefore no longer reflected in the content of the website.

As the website is no longer updated, we assume no liability for the content of this website, or the linked websites contained therein. The operators of the linked sites are solely responsible for their content.

Irrespective of this, you can still find the current BPCoC and the General Terms and Conditions of Purchase at Vitesco Technologies - Suppliers (vitesco-technologies.com)

Under the following link you will find the current Schaeffler website:

.jpg?width=407&resizemode=force)

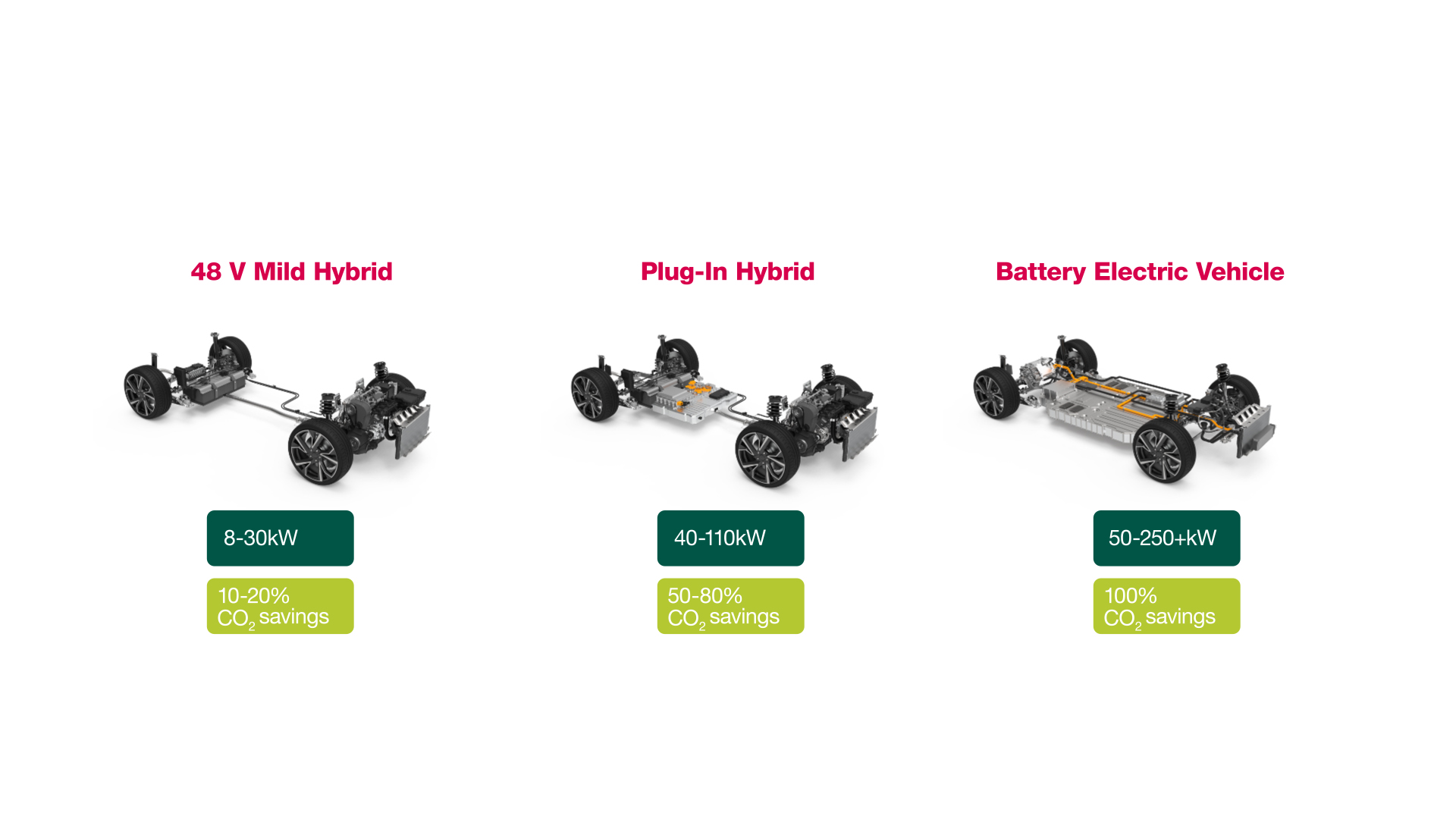

Regensburg, March 23, 2021. Vitesco Technologies’ clear electrification strategy, which was communicated at an early stage, meets rapidly growing global market demands. The company covers all applications with its technology mix for all key performance classes, from 48-volt to high-voltage drives.

With mild 48-volt hybridization, Vitesco Technologies is a pioneer, who delivered the first 48-volt systems back in 2016, building on experience of similar 42-volt technologies, that went into global volume production in 2006.

The actual growth is still in the starting blocks, as the legal pressure to reduce CO2 emissions from whole fleets and the requirements for reducing emissions are continuing to increase. The economical 48-volt systems help to save fuel by 10 to 20 percent depending on the application and driving distance.

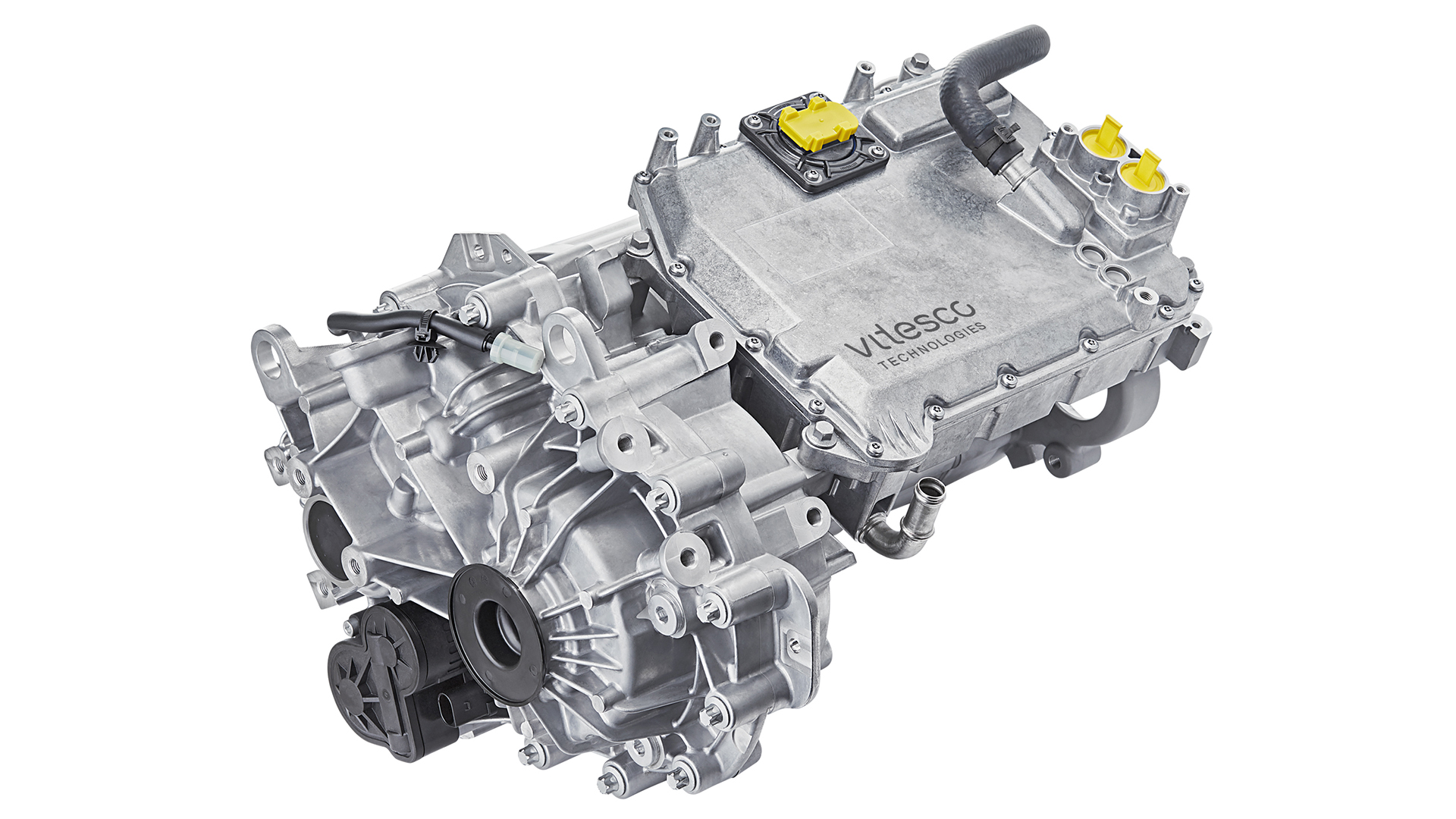

Vitesco Technologies already produces the integrated electrical final drive EMR3 – a compact, lightweight and high-performance combination of electric motor, inverter and reduction gear – for more than five manufacturers and for over 20 different vehicle models. Since the end of 2019, the company has delivered over 150,000 of these units. Another pioneering achievement: Electric vehicles with integrated electrical final drive received several awards last year for their good driving performance, price-performance ratio and energy efficiency.

The current market success – despite the ongoing Corona virus pandemic – was made possible by an early strategic orientation. The EMR3 high-voltage axle drive has a modular design and responds to the common market requirements in a solution that can be integrated into the vehicle at an attractive cost: The 3-in-1 system, consisting of an electric motor, inverter and reducer, offers the best possible performance values in terms of installation space, weight, performance, and costs in the performance class of 100 kW to 150 kW.

In order to successfully serve the growth that is kicking off in electrification, three strengths have been implemented in the drive portfolio for the volume market: "Consistent modularization makes it possible to scale drives economically for many types of vehicles and to reduce costs in both design and manufacturing," explains Katharina Helten, head of Mechanical Modules for Electric Drives.

© Vitesco Technologies GmbH (exclusive rights)

Progress in efficiency in the active parts contributes to driving pleasure and greater range. Also, the current range of performance requirements for high-voltage drives will become even more scalable in the future with 60 kW to 200 kW. There is also still potential for the energy efficiency of the drive system.

Both 48-volt and high-voltage systems benefit from the increasing quantities at Vitesco Technologies, as many basic requirements apply to both voltages. Here, the technological mix has repeatedly proven to be a source of synergies.

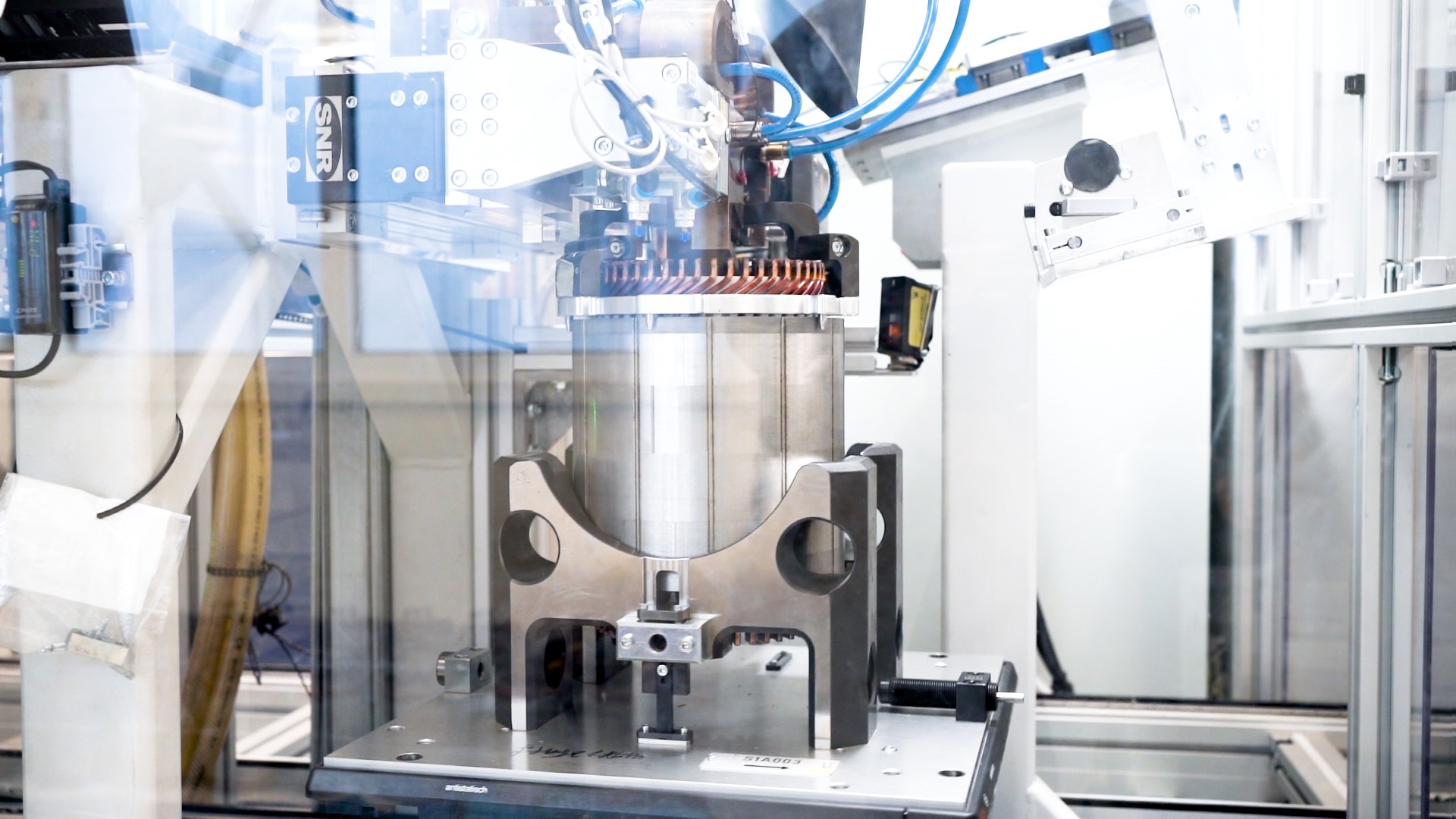

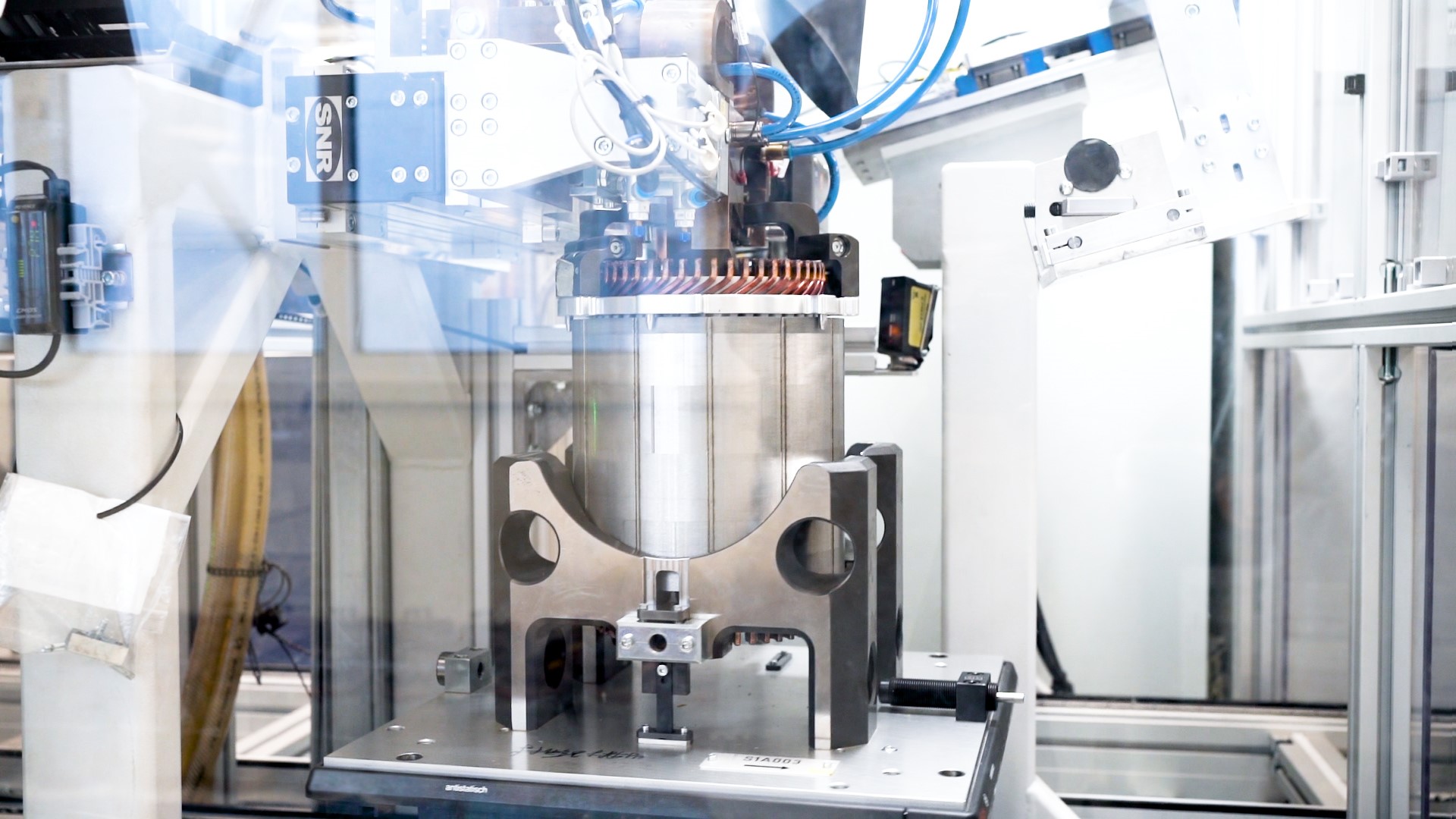

Rotor and stator of the integrated electric axle drive EMR3.

© Vitesco Technologies GmbH (exclusive rights)

The stator with its twisted I-pins (winding heads) is, together with the rotor, one of the two main components of the motor of the Integrated Axle Drive EMR3 from Vitesco Technologies. The product was developed in Berlin and Nuremberg as well as in Shanghai and Tianjin.

© Vitesco Technologies GmbH (exclusive rights)

The axle drive EMR3 is manufactured at the Vitesco Technologies site in Tianjin (China) for the volume market.

© Vitesco Technologies GmbH (exclusive rights)

Prototype of the Integrated Axle Drive (EMR3) from Vitesco Technologies: This picture shows how the connection current rails of the stator are brazed.

© Vitesco Technologies GmbH (exclusive rights)

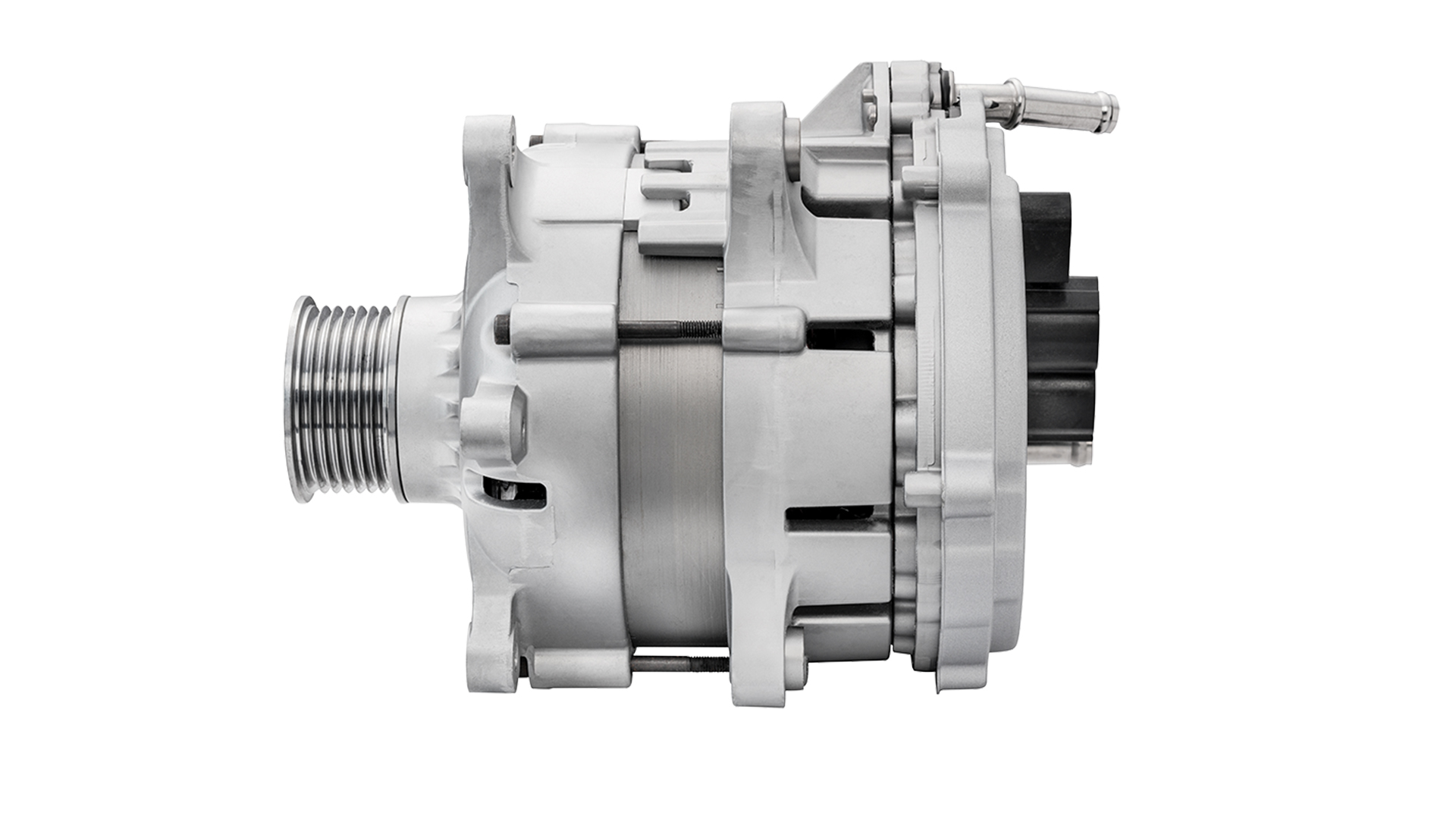

The 48 V belt-driven starter generator for mild hybrid systems can realize significant CO2-reductions while enhancing drivability.

© Vitesco Technologies GmbH (exclusive rights)

The 48 V DC/DC converter connects to voltage levels: 12V for the power net of the vehicle and 48 V for the components of the mild-hybrid-system.

© Vitesco Technologies GmbH (exclusive rights)

The 48 V belt-driven starter generator for mild hybrid systems can realize significant CO2-reductions while enhancing drivability.

© Vitesco Technologies GmbH (exclusive rights)

The Chinese auto group Dongfeng Passenger Car Corporation uses the integrated axle drive from Vitesco Technologies in its new electric passenger car model Yixuan.

© Vitesco Technologies GmbH (exclusive rights)

Vitesco Technologies' portfolio offers leading solutions for all electrification types.

© Vitesco Technologies GmbH (exclusive rights)

The Dongfeng Passenger Car Corporation version of the EMR3 delivers 120 kW of power, pushes out up to 260 Nm of torque but weighs less than 80 kilograms and is a highly compact, fully validated system that is easily designed-in to an electric vehicle.

© Vitesco Technologies GmbH (exclusive rights)